MartinPens

Member

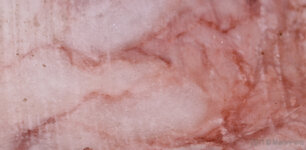

I have a 6.5 lb block of white Alibaster with some pink in it. It is basically 8 x 2 x 4 (removing the wings).

After reading about all it takes to turn one of these and get the grit out of everything, I'm not sure I'm up for it.

Any suggestions of someone whom I could send the block to and maybe get a round blank in return?

If you have worked with Alabaster, is this block figured enough (in your opinion) to even bother with? There is probably much nicer stuff out there. I may end up giving it away.

Martin

After reading about all it takes to turn one of these and get the grit out of everything, I'm not sure I'm up for it.

Any suggestions of someone whom I could send the block to and maybe get a round blank in return?

If you have worked with Alabaster, is this block figured enough (in your opinion) to even bother with? There is probably much nicer stuff out there. I may end up giving it away.

Martin