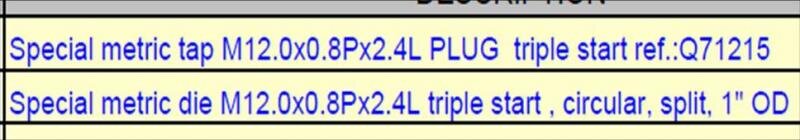

I have to disagree about the lack of need for multi start threads . The amount of turns to cap a pen is only one of the reasons for using multi start threading . I have made several pens with single start threading and found them to be unacceptable for sale for reasons related to strength and aesthetics . There is a reason that almost all of the major pen companies use multi start threading . Strength is very important in the threading of the cap and for a single start thread to be strong enough to stand up to years of use , you have to have as many threads in contact as you possibly can to spread out the stresses that the joint is subjected to . It has been said that just 3 threads are needed for a strong threaded connection but after allot of experimentation I have found that 3 threads will not stand up to the stresses of a pen cap and the joint will fail , in most cases the cap cracked . This means in general at least 8 to 12 threads for a normal acrylic pen cap . That many turns to tighten the cap would be totally unacceptable , I normally try to have at least 9 threads in contact on my pens made of acrylic to provide a strong joint . This is easily accomplished with just 3 turns of a triple start thread .

The other reason , aesthetics , is just as important . A strong single start threaded joint just looks and feels fugly . The large size of the threads feels very rough and uncomfortable for long writing sessions . Threads of that size also break up the flow of well made pen and distract the eye from the look of the rest of the pen .