bradleyheathhays

Member

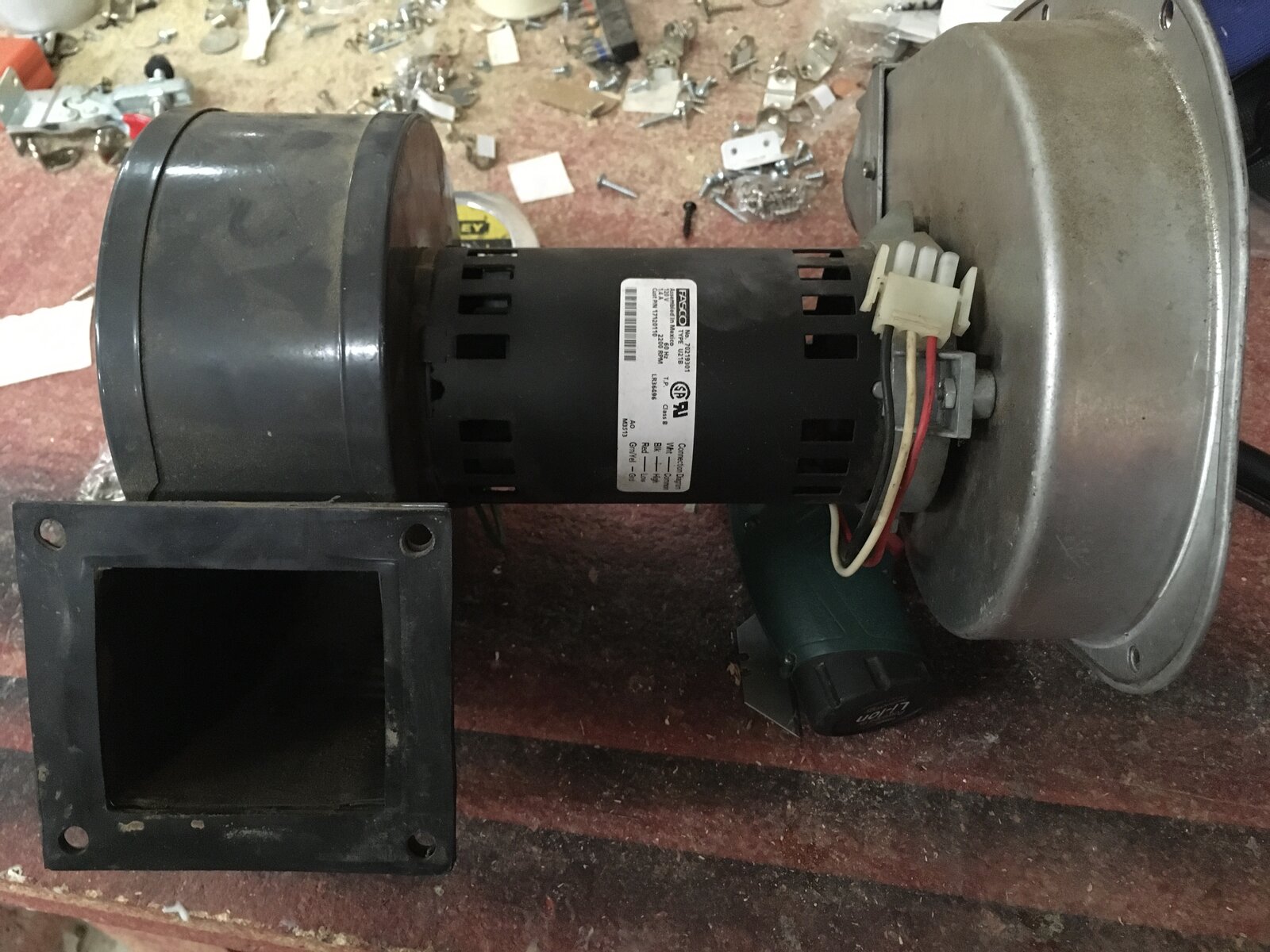

I have this blower motor that's out of a used pellet stove the previous owner says was going bad. I suspect it's because it was almost completely clogged at the intake, but I wanted to test it out electrically to make sure. The motor housing says 120v, so not know hardly anything about electricity I cut off the female end of an extension cord and proceeded to apply the two ends to the black and red wires at the wiring harness shown in the picture. Motor spun up just fine and I let it run for about 5 seconds, and when I pulled the wires off the motor was slightly smoking.

So I'm wondering...

1 - Since this is a 120v motor why did it smoke?

2 - What part smoked? Plastic inside the motor or solder?

3 - What's the likelihood I just killed this motor?

Thanks.

So I'm wondering...

1 - Since this is a 120v motor why did it smoke?

2 - What part smoked? Plastic inside the motor or solder?

3 - What's the likelihood I just killed this motor?

Thanks.