You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Tailstock Alignment Tool (?)

- Thread starter TonyL

- Start date

Signed-In Members Don't See This Ad

Signed-In Members Don't See This Ad

Skie_M

Member

Don't you usually just turn one out of scrap material for free???

Thats normally used with a dial indicator on a metal lathe to dial in the tailstock.

You can als turn a bar in your lathe and measure the ends to see if they are the same and start adjusting the tailstock if it needs it.

Its not really for wood lathes.

You can als turn a bar in your lathe and measure the ends to see if they are the same and start adjusting the tailstock if it needs it.

Its not really for wood lathes.

monophoto

Member

How does it work?

There are no instructions on the web site, but the one picture shows it suspended between centers. Seems to me that wouldn't accomplish very much. The tailstock could be misaligned, and the bar could still be supported between centers.

I don't need to spend $50 for that - an old broom handle would do the job.

There are no instructions on the web site, but the one picture shows it suspended between centers. Seems to me that wouldn't accomplish very much. The tailstock could be misaligned, and the bar could still be supported between centers.

I don't need to spend $50 for that - an old broom handle would do the job.

raar25

Member

I use a dual morse taper tool that I think I bought from Nova. Just stick one taper in the talk stock and slide the tail stock up and then tighten the headstock. This tool seems like it has too much room for error.

NOVA 2MTNA Acruline 2MT Alignment Lathe Accessory - Power Lathe Accessories - Amazon.com

NOVA 2MTNA Acruline 2MT Alignment Lathe Accessory - Power Lathe Accessories - Amazon.com

plantman

Member

Tony; It seems like a lot of money for a bar with 2 holes drilled in it !! I would think if you had a good drill press and an good centering vice, that you could make your own for a few dollars. Or, have a machine shop drill the holes for you. The object is to engage the head stock and the tail stock into the bar at a preset distance and see if it turns true without any deviation. This can be done by running the lathe at slow speed and moving the tail stock until it centers out. Or, as I do, you can use a dial indicator to center your tail stock while turning your lathe by hand. What may be dead center with your tail and head stock point to point, may not be dead center 12 inches down your lathe rails. Jim S

Last edited:

Ed McDonnell

Member

Metal lathe tailstocks can be adjusted off center if needed. Getting the tailstock back to dead center is important when you again want to turn cylinders without tapers. Your setup will only be as good (or as easy) as the tools you use to do the setup. Here's a video that shows how the bar Tony linked (or one you could make yourself) would be used.

https://www.youtube.com/watch?v=8iXC-nnZlG0

As Mike indicated earlier. It's not for wood lathes.

Ed

https://www.youtube.com/watch?v=8iXC-nnZlG0

As Mike indicated earlier. It's not for wood lathes.

Ed

Thanks for the feedback. Edge Technologies does have instructions and I do own a magnetic base and indicator.

Some things I like to make (pens), and some I rather buy.

Regardless of the tool used, one still has to know how to calibrate the tailstock.

Thanks for all of the links!

Some things I like to make (pens), and some I rather buy.

Regardless of the tool used, one still has to know how to calibrate the tailstock.

Thanks for all of the links!

Fish30114

Member

Tony, that's an interesting looking tool/approach, I don't have one but this one from Teknatool is pretty economical, and I have used one at a class I attended. Here's a link: Packard Woodworks: The Woodturner's Source: Morse Taper Alignment Tool

Might be worthwhile for the price difference---even given my disdain for Nova/ teknatool!

Might be worthwhile for the price difference---even given my disdain for Nova/ teknatool!

keithbyrd

Member

I use a dual morse taper tool that I think I bought from Nova. Just stick one taper in the talk stock and slide the tail stock up and then tighten the headstock. This tool seems like it has too much room for error.

NOVA 2MTNA Acruline 2MT Alignment Lathe Accessory - Power Lathe Accessories - Amazon.com

RAAR25 - I bought one of those but I am missing something on using it - how do you use it? I bought it a couple years ago and figure it out. if you have to loosen the 4 bolts on the tailstock to use it- since I have my lathe bolted to a table I can't get under the tail stock! any suggestions or experiences you care to share?

Fish30114

Member

Keith, if you have a Nova lathe, loosening those bolts on your tailstock is exactly what you need to do--sorry to tell ya--but once you do it is simple you simply slide your tailstock up to where the tool is in both the headstock and tailstock at the same time, and tighten up the locking bolts on your tailstock--interestingly, this is the same way we used this tool on Powermatic 3520 B's at the class I went to.

Fish30114

Member

Maybe I'm just too simple minded or I'm missing something here, but with a wood lathe isn't tip-to-tip still about as accurate as you can get, as well as the cheapest....free?

Bob, that's what I do currently, I can't detect whatever misalignment might remain doing it that way....

Sabaharr

Member

I use a dual morse taper tool that I think I bought from Nova. Just stick one taper in the talk stock and slide the tail stock up and then tighten the headstock. This tool seems like it has too much room for error.

NOVA 2MTNA Acruline 2MT Alignment Lathe Accessory - Power Lathe Accessories - Amazon.com

OK, saw this and seemed like a must have item so I ordered one. Only 16 left in stock.

Sabaharr

Member

Bob, tip to tip is a good indicator of gross misalignment but if both are cocked slightly in the same direction you would not know it tip to tip. Looks like the double ended MT2 tool will solve a load of guesswork from the equation so I have one on the way.

monophoto

Member

Maybe I'm just too simple minded or I'm missing something here, but with a wood lathe isn't tip-to-tip still about as accurate as you can get, as well as the cheapest....free?

Bob

Tip to tip assures that the tip of a headstock drive center is at the same point in space as the tip of the tailstock live center.

However, it does not assure that the axis of rotation of the headstock is aligned with the axis of rotation of the tailstock.

Here's a hypothetical worst case example - visualize the tailstock removed entirely from your lathe and you are just holding in air such that the axis of rotation of the tailstock is at 90 deg to the bedways. You can still touch the tip of the drive center to the tip of the live center, but the tailstock is about as far out of alignment as is physically possible.

My practical experience is that you can line up the tip of a headstock drive center with the tip of a tailstock live center and still have a problem. Minor misalignment will be amplified by any spindle-like device that you insert into the headstock - so I like to do my alignment by inserting a pen mandrel into the headstock spindle, and then aligning the end of the mandrel with the tailstock live center. Just make sure that the mandrel is perfectly straight - turn on the lathe at its lowest speed with the mandrel NOT touching the tailstock, and look for runout at the end of the mandrel.

Furthermore, you can have your headstock and tailstock perfectly aligned, and then introduce runout by using a headstock washer under a chuck that isn't perfectly flat. DAMHIKT

The tool under discussion here is used in combination with a dial indicator to measure how far out of alignment the tailstock is. The video that Ed posted is very helpful in understanding how it is used. My point is still valid - why spend $50 for something that you can make from an old broom handle for nothing.

shastastan

Member

Tony, that's an interesting looking tool/approach, I don't have one but this one from Teknatool is pretty economical, and I have used one at a class I attended. Here's a link: Packard Woodworks: The Woodturner's Source: Morse Taper Alignment Tool

Might be worthwhile for the price difference---even given my disdain for Nova/ teknatool!

I bought one like Packards. Although I don't have a lathe with outboard turning, I actually use this MT as an extension from the head stock as well as for alignment. I would rather have metal than wood for this tool.

Last edited:

Ed McDonnell

Member

...

The tool under discussion here is used in combination with a dial indicator to measure how far out of alignment the tailstock is. The video that Ed posted is very helpful in understanding how it is used. My point is still valid - why spend $50 for something that you can make from an old broom handle for nothing.

Hi Louie - Because something made from wood (broom handle or whatever) will not have the kind of accuracy that a typical metal lathe user is looking for. I like to set up my lathe so that I don't have more than a couple thousandths error over 12". A wooden dowel won't work. Something I make myself won't work either unless I already have my lathe dead on when I make it (and I can never get my little mini-lathe completely dead on). That said, I don't see the need to pay $50 for the piece Tony linked. There are plenty of alternatives that cost a lot less (although they may not look as pretty

Ed

Even if with there was something that brings the head and tail-stocks to "perfect" alignment or let you know you are misaligned, the correct positioning still has to be held in place by something. According Bobby of Jet, just level the legs - who knows.

This topic has my attention and if I can fine tune this even more, I am all ears.

What I do now is put in my drive center and live center with the sharpest points and run them tip to tip. I snug the tailstock down just a bit but not tight, then start extending the quill. If the tips are lined up in what I thought was straight, they would push the tailstock back and remain tip-to-tip.

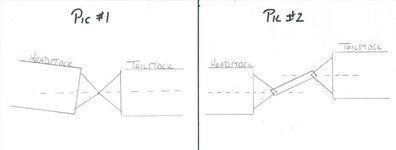

The comments above about them possibly not being on the same axis makes a lot of sense, (pic #1, exaggerated a bit) that I didn't give as much attention as I should. But in pic #2, what stops that alignment bar from being on a different plane or axis, even if only off by a hair? Would this not create an off center issue?

I know for a fact that the larger the piece is that I'm turning, the more amplified even the smallest difference gets to be. Hopefully this will be one of those Ahh-Haa moments.

Never too experienced to stop learning...

What I do now is put in my drive center and live center with the sharpest points and run them tip to tip. I snug the tailstock down just a bit but not tight, then start extending the quill. If the tips are lined up in what I thought was straight, they would push the tailstock back and remain tip-to-tip.

The comments above about them possibly not being on the same axis makes a lot of sense, (pic #1, exaggerated a bit) that I didn't give as much attention as I should. But in pic #2, what stops that alignment bar from being on a different plane or axis, even if only off by a hair? Would this not create an off center issue?

I know for a fact that the larger the piece is that I'm turning, the more amplified even the smallest difference gets to be. Hopefully this will be one of those Ahh-Haa moments.

Never too experienced to stop learning...

Attachments

Skie_M

Member

You should watch that video someone posted earlier, about how to align your lathe (metal lathe).

As a metalworking lathe has a cross-feed and additional ways, you can ensure repeatability of an action, like measurements. You don't have that with a wood lathe, but you could still give yourself a consistent point of reference.

You could turn a round dowel (using calipers) to a uniform thickness, and measure (with dial indicators) the distance from the lathe bed to the ends of the rod... check for a difference in height.

As for checking side to side, you'll have to mount something on the ways that is a true flat and align it with the ways so that it is perfectly parallel, and then use the dial indicators from that new reference to check horizontal alignment.

In most cases you could just check from the front of your lathe bed ways and the back edge ... as long as the 2 dial indicators are precisely aligned with each other, they should give you a reasonably accurate measure of how far off from dead center you are. This method should be close enough for woodworking accuracy. (affix a board via clamps as a backstop to give you an accurate measuring point)

As a metalworking lathe has a cross-feed and additional ways, you can ensure repeatability of an action, like measurements. You don't have that with a wood lathe, but you could still give yourself a consistent point of reference.

You could turn a round dowel (using calipers) to a uniform thickness, and measure (with dial indicators) the distance from the lathe bed to the ends of the rod... check for a difference in height.

As for checking side to side, you'll have to mount something on the ways that is a true flat and align it with the ways so that it is perfectly parallel, and then use the dial indicators from that new reference to check horizontal alignment.

In most cases you could just check from the front of your lathe bed ways and the back edge ... as long as the 2 dial indicators are precisely aligned with each other, they should give you a reasonably accurate measure of how far off from dead center you are. This method should be close enough for woodworking accuracy. (affix a board via clamps as a backstop to give you an accurate measuring point)

Fish30114

Member

Bob, I'm not sure about most things in life anymore, but I think that what happens with the solid tool, is that the headstock and tailstock are forced into whatever alignment comes through the tool from the headstock to the tailstock--with the tool I posted a link to--the tailstock adjustment bolts are loosened and then tightened so the tailstock is 'slaved' to the headstock--hope that helped more than confused--but who knows....

Good point Tony--where are you Ken?

Good point Tony--where are you Ken?

Last edited:

TurtleTom

Member

How does it work?

There are no instructions on the web site, but the one picture shows it suspended between centers. Seems to me that wouldn't accomplish very much. The tailstock could be misaligned, and the bar could still be supported between centers.

I don't need to spend $50 for that - an old broom handle would do the job.

In order to use it between centers the lathe must have an accurate carriage, and wood lathes don't have carriages. More the pity.

plantman

Member

Several points of interest. 1- If you make your alignment tool out of wood, any change in humidity, heat, wear, or pressure will effect the alignment !! 2- For those of us who also have mini lathes with a #1 MT, Sherline makes a Lathe Buddy alignment tool with a MT1 to MT1 taper $25.99. They also make MT0 to MT0, MT1 to MT0, and several others. 3- When I restore a wood lathe that is not turning true or straight, I drill and tap the tail stock where it comes in contact with the rails, and install set screws to hold the alignment side to side. If your alignment is off up or down, you may have to add shim stock or remove a little material from the front of our tail stock. Set screws are the method used on most metal lathes to correct alignment, and when you have a multi-axis metal lathe, you need an alignment bar to bring it back to true center quickly. 4- Most wood lathes are not made to be precise tools. If you are off 30 thousands from end to end on a 3 foot table leg or bowl rim, nobody will notice, however if you are off that amount on a 5 1/2 inch pen, nothing will line up and it will definitively be noticed. 5- I'm sorry Tony, but leveling the legs on your lathe is the dumbest solution I have heard in a long time. I have nothing against having your tools level, but If the frame of your lathe is that flexible that leveling the legs will bring it back into alignment you need a better lathe !! If your frame is rigid and bolted down to a work bench , you could turn your projects at a 45 degree angle and it wouldn't make any difference. 6- 90 % accurate is not close enough for any turning project !!. You should be able to get your lathe to dead center or within a few 1000's over the length of your rails. 7- Another solution would be to chuck a pencil laser ( $5 ) into your head stock and a half inch round rod into your tail stock, move the tail stock to the end of your rails and align. Use a rod that is larger than the dot on your laser so you can center it on your rod end. Once aligned, you will still need some type of adjustment screw to hold the tail stock in that position. If your rails are not perfect, you may have to realign at different positions along the rail. Excuse the long winded answer, but I like to cover everything in detail in one thread. Jim S

Last edited:

"5- I'm sorry Tony, but leveling the legs on your lathe is the dumbest solution I have heard in a long time. "

Nothing to be sorry about.

It didn't make much sense to me, but that is what at two Jet tech support guys told me a year apart; and it's what many wood turning forums say. That doesn't make it right --- just popularly wrong I guess.

Nothing to be sorry about.

It didn't make much sense to me, but that is what at two Jet tech support guys told me a year apart; and it's what many wood turning forums say. That doesn't make it right --- just popularly wrong I guess.

They are telling you to level the legs to level the lathe bed. IF the front of the lathe near the headstock is out of level one way and the legs at the tailstock the other, the two will not be aligned. I had an Atlas 10 metal lathe that I could put a dial indicator on and measure the tweak on the bed as I pushed the head stock back and forth.

When setting up a metal lathe we use a machinest level to get the lathe as close to 0 difference as humanly possible to the point where temperature has to be taken into account.

Use one of the levels that is accurate to .005 on both ends and get them as close to the same as you can. I know my Empire brand levels are rated for that.

When setting up a metal lathe we use a machinest level to get the lathe as close to 0 difference as humanly possible to the point where temperature has to be taken into account.

Use one of the levels that is accurate to .005 on both ends and get them as close to the same as you can. I know my Empire brand levels are rated for that.

Ed McDonnell

Member

When they talk about "leveling" the lathe, they are really addressing the issue of removing twist from the lathe bed. Bed twist is one of the causes (but not the only cause) of misalignment between the headstock and tailstock. How important that alignment is depends on how you use the lathe.

For bowl turning on a wood lathe it would have to be really bad to notice.

For spindle turning (including pens) it can be more important to have good alignment.

For doing anything on a metal lathe, any twist in the bed is unacceptable.

You remove the twist by adjusting the lathe feet to "level" the lathe and remove the twist. For a wood lathe, use of a digital level at three points along the lathe bed is probably more than adequate to allow you to remove twist.

Ed

For bowl turning on a wood lathe it would have to be really bad to notice.

For spindle turning (including pens) it can be more important to have good alignment.

For doing anything on a metal lathe, any twist in the bed is unacceptable.

You remove the twist by adjusting the lathe feet to "level" the lathe and remove the twist. For a wood lathe, use of a digital level at three points along the lathe bed is probably more than adequate to allow you to remove twist.

Ed

Last edited:

oneleggimp

Member

http://www.amazon.com/Mitutoyo-950-201-Center-Gage-Threads/dp/B002SG7R1Y

Many of the preceding responses have thoroughly covered the bar Tony shared with us. Another "quic and Dirty" approach used by some machinists to realign the tailstock of a metal lathe with the headstock is to use this tool. Even though it says it's for threading and is used for that - it is also used for getting alignment close to back to normal before any indicating It has two 60 degree notches directly across from each other. You put a 60 degree center in the headstock and a 60 degree center in the tailstock. Put the points of the two centers - one in each notch and tweak the tailstock until both centers fit in their respective notches fully - so that they touch the sides of the notch without any gaps. Often then machinists will go ahead and put a true bar (such as the one Tony showed us) between centers and indicate to correct any runout. With a wood lathe if the centers line up using this cheapie tool, it' probably "close enough for jazz (i.e. woodwork). I've shown the Mitutoyo one (Japanese made and very good quality) at about $13.00. Starrett also makes at one over twice the price ($30.00). This tool is what I use to check alignment between centers on a wood lathe. For what it's worth.

Many of the preceding responses have thoroughly covered the bar Tony shared with us. Another "quic and Dirty" approach used by some machinists to realign the tailstock of a metal lathe with the headstock is to use this tool. Even though it says it's for threading and is used for that - it is also used for getting alignment close to back to normal before any indicating It has two 60 degree notches directly across from each other. You put a 60 degree center in the headstock and a 60 degree center in the tailstock. Put the points of the two centers - one in each notch and tweak the tailstock until both centers fit in their respective notches fully - so that they touch the sides of the notch without any gaps. Often then machinists will go ahead and put a true bar (such as the one Tony showed us) between centers and indicate to correct any runout. With a wood lathe if the centers line up using this cheapie tool, it' probably "close enough for jazz (i.e. woodwork). I've shown the Mitutoyo one (Japanese made and very good quality) at about $13.00. Starrett also makes at one over twice the price ($30.00). This tool is what I use to check alignment between centers on a wood lathe. For what it's worth.

All great stuff. I would say I am pretty much dead-on for a wood lathe ($700 Jet wood lathe...considering one can easily spend thousands and 10s of thousands). I cannot feel a elliptical barrel even with a Long Clicker. I like gadgets or to learn "tricks" that have the opportunity to improve things - even if I don't feel or see the imperfections. I learned volumes from you all. Thank you.

Which Empire level?

Empire Level - Box Levels

for a 1221 and 1015

Just having some fun, but I do like tools. May get one.

Empire Level - Box Levels

for a 1221 and 1015

Just having some fun, but I do like tools. May get one.

PenPal

Member

Hi Tony my method I have used for ever it seems came to me from my metal lathe instructions 50 yrs ago put a dead centre in the head stock and the tail stock bring them together almost lock the tail stock bring the the quill forward gently with a thin guage as you use to measure plug gaps in a spark only very thin at the point of touching the thin gauge can deflect b360 degrees showing if the alignment is true if not in which direction is it incorrect.

Peter.

Peter.

Yep Peter. that's nice and simple and a similar method of checking correct ML tool height

Your method is great if you deliberately mis-align your tailstock to turn a taper and then want to reset it, provided ( as has been metioned ) there is no twist in the bed. If you know there is no twist, then the short distance used during the test isn't an issue.

Your method is great if you deliberately mis-align your tailstock to turn a taper and then want to reset it, provided ( as has been metioned ) there is no twist in the bed. If you know there is no twist, then the short distance used during the test isn't an issue.

TurtleTom

Member

The tailstock taper can be 45 degrees to the headstock taper and the points can still meet. This is the extreme case but lesser angles produce undesirable errors too.

Last edited:

TurtleTom

Member

I use a dual morse taper tool that I think I bought from Nova. Just stick one taper in the talk stock and slide the tail stock up and then tighten the headstock. This tool seems like it has too much room for error.

NOVA 2MTNA Acruline 2MT Alignment Lathe Accessory - Power Lathe Accessories - Amazon.com

OK, saw this and seemed like a must have item so I ordered one. Only 16 left in stock.

Thanks for this, I have one on the way.

The tailstock taper can be 45 degrees to the headstock taper and the points can still meet. This is the extreme case but lesser angles produce undesirable errors too.

They would only meet if the tailstock was deliberately extended / retracted to the exact point. Any variation to the tailstock extension / retraction would make make the gauge move massively.

I think it would be highly unlikely they would randomly align.....:wink:

Last edited:

Paul in OKC

Member

Wow, I still get amazed at topics like this. If we are talking wood lathes, these are not precision machines. Since cutting is done with hand held tools, that is what controls taper and such. Out of aligned head/tail stocks mean nothing really. If they are so far out the it cause strain, then you have a problem. If they have adjustable tail stocks like metal lathes, then tweak them in. If not, then something is really wrong with the lathe in the first place. Bed twist is a concern on machines, wood or metal. Short beds there is not a lot you can do, but long beds it is noticeable. I have two Jet 10x14 wood lathes and I have never done any kind of head/tail alignment check. That bar is for metal lathes.

TurtleTom

Member

The tailstock taper can be 45 degrees to the headstock taper and the points can still meet. This is the extreme case but lesser angles produce undesirable errors too.

They would only meet if the tailstock was deliberately extended / retracted to the exact point. Any variation to the tailstock extension / retraction would make make the gauge move massively.

I think it would be highly unlikely they would randomly align.....:wink:

I need to introduce you to an acquaintance of mine, Mr. Murphy.:wink:

And of course I already proved you can drill a straight hole by hand without the use of the tailstock but we are inherently precise and enjoy the machines.

Signed-In Members Don't See This Ad

TurtleTom

Member

I received my alignment bar yesterday and checked the lathe. I can't believe it was that good. Thanks Rikon, sorry I doubted you.