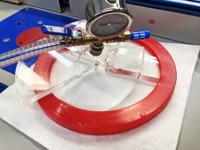

View attachment 322552From Yescom chamber on Amazon.

Question:

What is the issue with using Cactus Juice?

Answer:

I use Cactus Juice in my vacuum chamber all the time with no issues. Of course, I use smaller glass jars with the Cactus Juice inside the vacuum chamber to ease with cleanup. This is a very nice vacuum chamber and I have been very pleased. No leaks at all.

By Robert S. on December 28, 2019

I have no direct experience but I read that Cactus Juice will permanently fog or scar the surface of plastic type lids and you can not see the bubbles. I bought this one because it has a glass lid which is okay with cactus Juice.

By Lifelong Tech on December 28, 2019

This is a great vacuum chamber but I use it as my secondary vacuum chamber after I have extracted the majority of the oxygen from my wood. It can bring atmospheric pressure to a near perfect vacuum but it doesn't regulate quickly which can easily result in a "boil over" of what ever brand of stabilizing resin you are…

see more

By Amazon Customer on December 28, 2019

I didn't have no issue just had to make sure it is fully covered with an inch of juice or so over the top

By Amazon Customer on December 29, 2019

It is just the manufacturer covering their backside. I have used it in this for years now.

By James L. Wright on December 29, 2019

From customers Questions on the unit I purchased with the glass lid.

That compatibility statement is a CYA. I've been using mine since Sept 2020 and have run over 8 gallons of Cactus Juice through it.

And the following is directly off Turntex website

Acrylic can indeed be used for a lid IF it is sufficiently thick enough. Cactus Juice, in direct contact with the acrylic for extended periods, can case a slimy film to build up on the acrylic but you lid should not be in direct contact to begin with.

Some chamber manufacturers claim that Cactus Juice will cause the lid to crack due to "fumes" but they do not understand the chemistry of Cactus Juice. There are no "fumes" from Cactus Juice, even under full vacuum. Most acrylic lid failures are caused by insufficient thickness of the acrylic.