PenPal

Member

My method of squaring pen blanks after glueing and cutting.

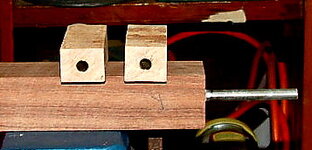

Construction method.

A small block of Aussie Ironwood horizontally bored to fit mandrel.

Using a Dremel with black cutting disk cut small grooves in the recessed part of the mandrel to allow glue movement all round the mandrel with random cuts around as well.

Used top class Epoxy Glued in place.

Cut the mandrel protuding to less than the blank length.

Place the block with mandrel against the rest on my Sander slide by hand gently to the disk.

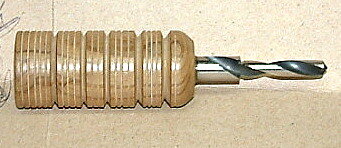

Clean up the ends using my 15 yr old Step Drill the only reamer available to pen turners then (made in the USA).

Easy breezy and smooth as, accurate.

Regards Peter.

Construction method.

A small block of Aussie Ironwood horizontally bored to fit mandrel.

Using a Dremel with black cutting disk cut small grooves in the recessed part of the mandrel to allow glue movement all round the mandrel with random cuts around as well.

Used top class Epoxy Glued in place.

Cut the mandrel protuding to less than the blank length.

Place the block with mandrel against the rest on my Sander slide by hand gently to the disk.

Clean up the ends using my 15 yr old Step Drill the only reamer available to pen turners then (made in the USA).

Easy breezy and smooth as, accurate.

Regards Peter.

![DSCF0001 [].JPG](/data/attachments/13/13129-781d2275afb98fc4d029b2fbf4e3e108.jpg?hash=eB0ida-5j8)