Wmcullen

Member

I'm not sure if this process is right or wrong; unique or common. But it works for me and I want to share in case it's interesting. |

17: Sanding facets with homemade drum for pens

last post:16-Facet-ilitating a New Project

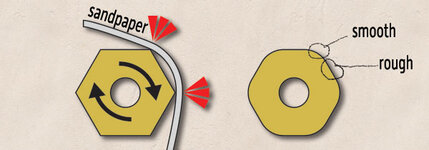

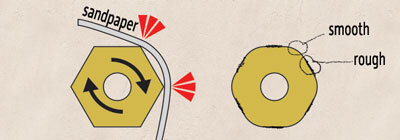

Homemade sanding drums are well-known and easily made. I decided to make mine specific for pens by including 4 different levels of grit. It works well and gets the job done quickly.

last post:16-Facet-ilitating a New Project

Homemade sanding drums are well-known and easily made. I decided to make mine specific for pens by including 4 different levels of grit. It works well and gets the job done quickly.

The Problem

When making a faceted pen with straight sides, sanding on a lathe becomes impractical.

My Solution

(Not rocket surgery, just how I did it.)

1. Cheap 2x4 pine cut and drilled with a 0.25" hole lengthwise.

2. Turned it round... no specific diameter... just round.

3. Installed a 5.5" long 0.25" bolt, washer and nut.

4. Cut a trench down the middle with a handsaw.

5. Shoved sandpaper into trench, wrapped around drum and cut so there was no overlap. Affixed with a small amount of glue.

Note: think through which direction the drum will spin before wrapping sandpaper.

6. The drum has 4 grits. Each facet can quickly hit each stop.

Note: Putting the segments on a bolt gave me much more control and accuracy than trying to hold the segment freehand.

Summary

I'm sure there are a billion methods to sand straight pen facets but I like the one I'm using and wanted to share.

Thanks for looking

- Cullen