johncrane

Member

Lee here are the photos and how l done my recessed clip.

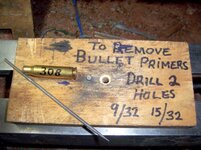

1] place primer end into hole then knock out primer using a small round file.

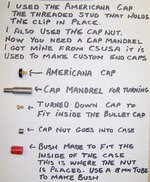

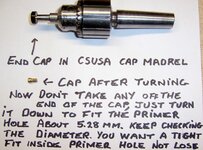

2] drill a 4mm hole all the way thru primer hole, then drill another hole 13/64 don't go all the way thru this time leave a bit of brass there to hold the threaded stud the 3rd photo shows this small lip that holds the threaded stud

4th photo parts l used, a cap mandrel from csusa,a Americana end cap & nut a gun clip. 5th photo shows cap size.

1] place primer end into hole then knock out primer using a small round file.

2] drill a 4mm hole all the way thru primer hole, then drill another hole 13/64 don't go all the way thru this time leave a bit of brass there to hold the threaded stud the 3rd photo shows this small lip that holds the threaded stud

4th photo parts l used, a cap mandrel from csusa,a Americana end cap & nut a gun clip. 5th photo shows cap size.