Keith, looks like Ulus are pretty close to finishing. The wooden one looks like it just needs some final shaping, sanding and finishing. I don't know if you're going to keep the nuts and bolts--looks like the wood as already been recessed for them. It will be utilitarian that way, so the knife can be disassembled if needed. Doing the wood will be pretty much like doing a wooden pen. There are many options for a finish, including CA (when I did my wooden handles I spread the CA with my finger--pulling it out a small drop at a time while wearing a nitrile glove).

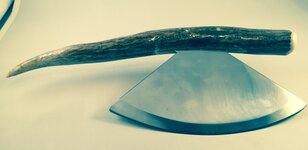

Can't see the other side of the stag handled Ulu, perhaps it has nuts on the other side? I think it would look great with brass or silver pins. You'll have to shape and sand the stag before final assembly.

The hunting knife has a rat-tail tang. I can't see if the end is threaded or not. If not, you could probably cut some with a die if you wanted to add an end cap. Also, I don't see a guard in the photo, you'll need one and there is delicate fitting involved to get it to mate up with the blade perfectly. Guards can be silver soldered on, or for an easier solution, affixed using JB Weld (which is what I did on the Bowie in my previous post). End cap or not, the hole in the handle would be filled with epoxy (I'd cut some notches in the tang for the glue to grab, sort of like roughing up a pen tube). If you're careful, it looks like there is enough meat in the tang so you could add a pin. Tangs are generally left fairly soft, so they can be worked (and so they won't snap as easily as they would if hardened).

As Peter points out, there are many vids and forums out there pertaining to knife making. Do post pics when you get them done!

Regards,

Michael