Penultimate

Member

Greetings

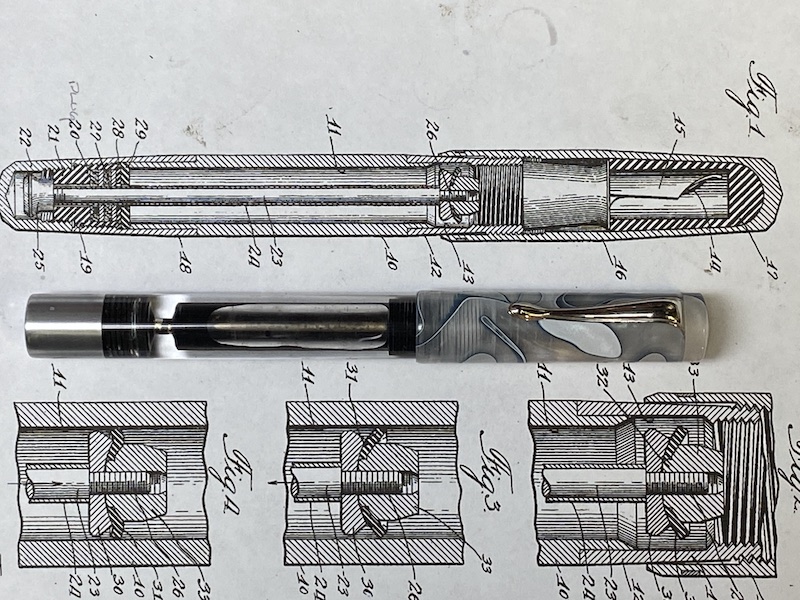

I've been working on a plunger filler design based on the 1930's Shaeffer patent. I started with a proof of concept then some prototyping. Here is the prototype that worked. It's kinda rough with mis-matched parts like an Aluminum finial cap, the slug was just the right size. It's needs more refinement but I'm putting this in my pen rotation to check for leaks and writing performance.

Parts:

body and nib section: clear cast acrylic

Plunger: brass shaft, Buna-N disc seal, I had to make a punch for the ID, clear acrylic parts that hold the seal in place. One is flat to support the seal when filling and the other part is spherical to allow the seal to deform and left the air in reservoir evacuate. Acetal finial to push on.

The sealing sealing system in the body at the finial consists of a couple o-rings, felt gasket soaked in mineral oil and a flat rubber disc. This is all compressed with the Acetal threaded plug. I milled a slot in the top of the plug to use a snap-ring pliers to tighten it.

The cap is an acrylic blank and clip.

Operation:

This differs from a syringe type plunger where you pull up on the shaft to draw ink into the reservoir. I've made a couple syringe fillers and half the pen is taken up by the shaft when the reservoir is full. The plunger filler works the opposite way. the plunger is pull up to the end of the reservoir slowly compressing and then evacuating the air behind it. When the plunger is pulled out you quickly depress the plunger. This creates a vacuum behind the seal. At the end of the stroke the seal moves into a relief diameter. The vacuum draws the ink into the reservoir. When I finally got my proof o' concept to work I couldn't stop filling the reservoir. It's cool to see the ink get pulled in.

Thanks for looking. Comments appreciated.

I've been working on a plunger filler design based on the 1930's Shaeffer patent. I started with a proof of concept then some prototyping. Here is the prototype that worked. It's kinda rough with mis-matched parts like an Aluminum finial cap, the slug was just the right size. It's needs more refinement but I'm putting this in my pen rotation to check for leaks and writing performance.

Parts:

body and nib section: clear cast acrylic

Plunger: brass shaft, Buna-N disc seal, I had to make a punch for the ID, clear acrylic parts that hold the seal in place. One is flat to support the seal when filling and the other part is spherical to allow the seal to deform and left the air in reservoir evacuate. Acetal finial to push on.

The sealing sealing system in the body at the finial consists of a couple o-rings, felt gasket soaked in mineral oil and a flat rubber disc. This is all compressed with the Acetal threaded plug. I milled a slot in the top of the plug to use a snap-ring pliers to tighten it.

The cap is an acrylic blank and clip.

Operation:

This differs from a syringe type plunger where you pull up on the shaft to draw ink into the reservoir. I've made a couple syringe fillers and half the pen is taken up by the shaft when the reservoir is full. The plunger filler works the opposite way. the plunger is pull up to the end of the reservoir slowly compressing and then evacuating the air behind it. When the plunger is pulled out you quickly depress the plunger. This creates a vacuum behind the seal. At the end of the stroke the seal moves into a relief diameter. The vacuum draws the ink into the reservoir. When I finally got my proof o' concept to work I couldn't stop filling the reservoir. It's cool to see the ink get pulled in.

Thanks for looking. Comments appreciated.