mgoetzke

Member

After a break I'm back to turning. I was into bowls but wanted to break myself in with some spindle turning so decided on pens since I have a stash of blanks. I'm enjoying the process of turning pens more than I thought I would. I also purchased a nice Crown/Colwin Way 1-1/4" skew chisel that I really like for the couple of pens I have completed so far (ha - don't think I ever used one before).

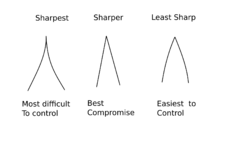

When it came time to sharpen I freehand ground it on my 8" CBN wheel, but, then I thought "now I just put a hollow grind on my skew." So this has generated a few questions:

1) Is it important to flat grind a skew or is a hollow grind OK?

2) If hollow grind is OK, do you freehand (like I did the first time) or do you use a jig like the Wolverine skew jig for consistency?

3) I see some use a CBN or diamond card between sharpenings - do you?

4) Seems like flat grinding at the grinder with a CBN wheel with grit on the sides requires a lot of skill. How do others do this?

Thanks

When it came time to sharpen I freehand ground it on my 8" CBN wheel, but, then I thought "now I just put a hollow grind on my skew." So this has generated a few questions:

1) Is it important to flat grind a skew or is a hollow grind OK?

2) If hollow grind is OK, do you freehand (like I did the first time) or do you use a jig like the Wolverine skew jig for consistency?

3) I see some use a CBN or diamond card between sharpenings - do you?

4) Seems like flat grinding at the grinder with a CBN wheel with grit on the sides requires a lot of skill. How do others do this?

Thanks