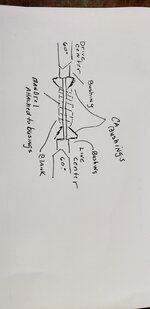

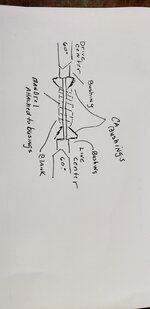

I don't link to remove 60 degree centers when applying CA. I was thinking of attaching to TBC bushings to each end of a mandrel - at least one may have to be threaded so allowing the CA bushings and blanks to ride along the mandrel. See my attempt to draw it below.

The idea is not to remove the drive and live centers - simply place this gizmo in between them. I would make it long enough to accept at least 2 long barrels.

Rick Herrell..are you listening? , better yet I will call you.

, better yet I will call you.

PS. I have placed CA bushings directly on my 60 degree centers, but it is a PITN to eliminate the wobble.

The idea is not to remove the drive and live centers - simply place this gizmo in between them. I would make it long enough to accept at least 2 long barrels.

Rick Herrell..are you listening?

PS. I have placed CA bushings directly on my 60 degree centers, but it is a PITN to eliminate the wobble.