I'm curious if anyone knows of any pinstripe pen blanks. I'm trying to think of some kind of "upper class" style of pen blanks, have for a while actually. I have a few ideas, but after starting to re-watch House of Cards, I noticed all the upscale suits, ties, upholstery, etc. and I started getting more ideas. I noticed just how much pinstripe there is in that show. I have some casein pinstripe blanks, whiter in color, that I've picked up from a few places. They are not always perfectly strait stripes, and not always even.

I am wondering if anyone has come across any proper pinstripe blanks, in some classy colors. Say a navy blue, with lighter pinstripes, or a charcoal gray with a lighter gray pinstripe, or even some of that lighter yellowish gold, with lighter yellow pinstripes.

I'm also curious, as I'll probably have to make some of the more exotic designs I'm thinking of myself...how one might go about making their own pinstripe blanks. I have one idea myself, which involves casting some solid color base blanks, turning them round, slicing them in half and sandwiching some material for the pinstripe color, then slicing that in half again and repeating the process several times. I suspect that will not give me exactly the look want, as I'm sure there will be some kind of offset problem between the size of the kerf and the thickness of the pinstripe material, etc. I'm sure there is a better, more reliable way to make such blanks.

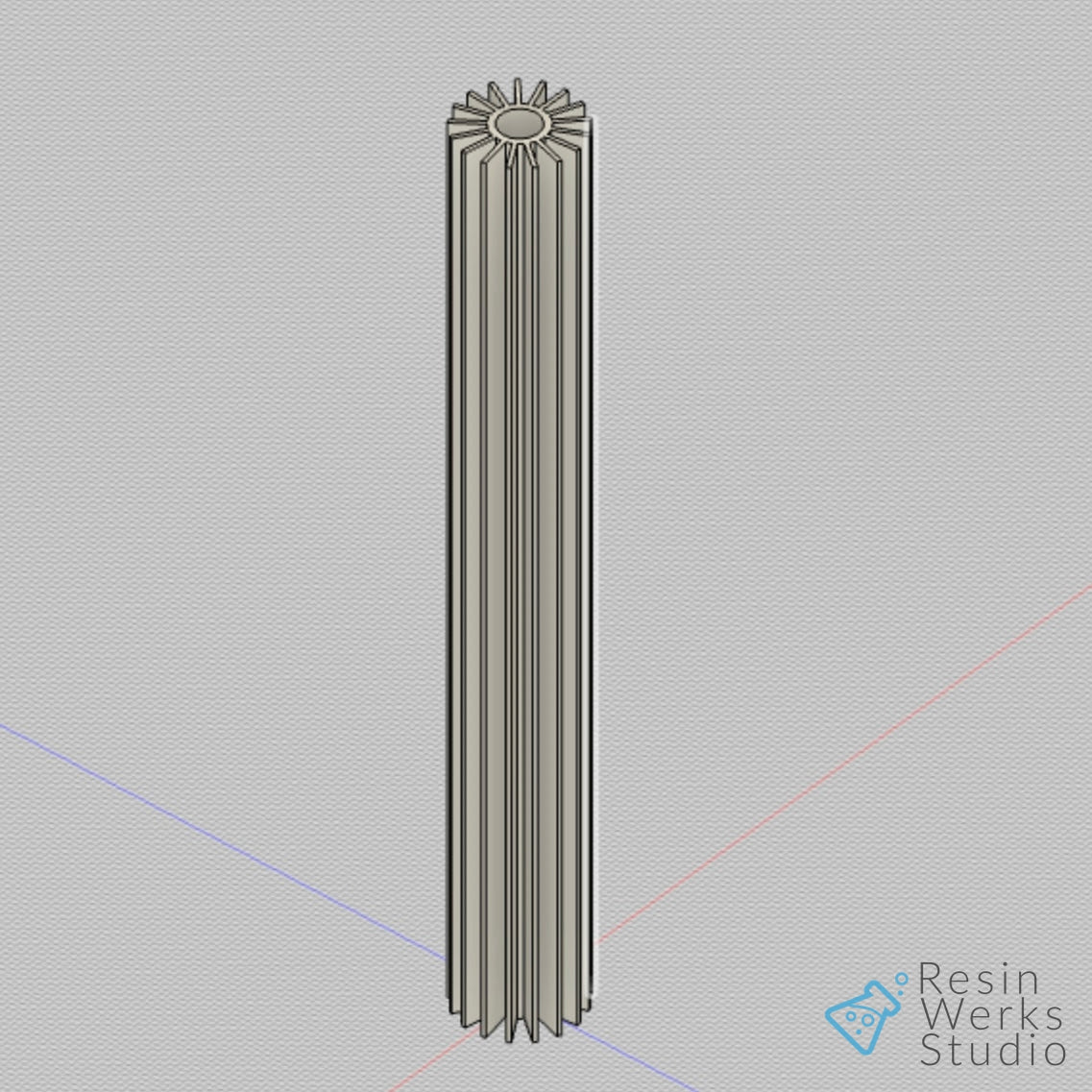

I also want to make blanks with stripes of alternating sizes, which I'm sure would require a more advanced technique, as well as blanks that maybe have certain shapes embedded in some of the stripes (i.e. circles, maybe diamonds, etc.) I'm starting to think, I may need a mill to do this...

I am wondering if anyone has come across any proper pinstripe blanks, in some classy colors. Say a navy blue, with lighter pinstripes, or a charcoal gray with a lighter gray pinstripe, or even some of that lighter yellowish gold, with lighter yellow pinstripes.

I'm also curious, as I'll probably have to make some of the more exotic designs I'm thinking of myself...how one might go about making their own pinstripe blanks. I have one idea myself, which involves casting some solid color base blanks, turning them round, slicing them in half and sandwiching some material for the pinstripe color, then slicing that in half again and repeating the process several times. I suspect that will not give me exactly the look want, as I'm sure there will be some kind of offset problem between the size of the kerf and the thickness of the pinstripe material, etc. I'm sure there is a better, more reliable way to make such blanks.

I also want to make blanks with stripes of alternating sizes, which I'm sure would require a more advanced technique, as well as blanks that maybe have certain shapes embedded in some of the stripes (i.e. circles, maybe diamonds, etc.) I'm starting to think, I may need a mill to do this...