As soon as I opened the box, I knew that the handle material i originally planned simply would not work. No firewood handles for this tool.

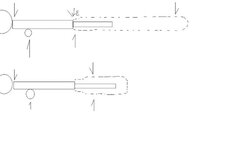

The handle is Homebrew PR with three colors of Mica. turned, and kinda sanded with some worn out 600. I am weird about my tool handles. I don't like to spend alot of time sanding and finishing them. I prefer the natural petina of time and sweat! ferrulle is a hose clamp.

The manufacturers, Our very own Bitshird (Ken), and Animefan (Andrew) of the famed http://www.woodchuck-tools.com did the engraving work. The engraving isn't just a scratch in the top of the tool. You would ruin the tool if you tried to grind it away. Excellent work!

Not all, but ALOT of the work of making this handle was done with the tool itself.

The handle is Homebrew PR with three colors of Mica. turned, and kinda sanded with some worn out 600. I am weird about my tool handles. I don't like to spend alot of time sanding and finishing them. I prefer the natural petina of time and sweat! ferrulle is a hose clamp.

The manufacturers, Our very own Bitshird (Ken), and Animefan (Andrew) of the famed http://www.woodchuck-tools.com did the engraving work. The engraving isn't just a scratch in the top of the tool. You would ruin the tool if you tried to grind it away. Excellent work!

Not all, but ALOT of the work of making this handle was done with the tool itself.