Just a thought on the lathe stand. I have a Delta long bed with a 6" swing (turn things up to about 10" diameter). I turn bowls, platters, and vases, in addition to pens.

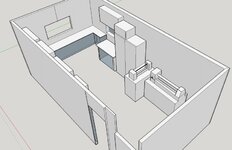

Built a cabinet from an old formica kitchen countertop. Mounted it on a cabinet with casters and leveling jacks to lift it up off the floor for stability. Cabinet has 3 drawers for storing lathe accessories, and an open area on the bottom for wood storage. Thought I would love it, but ...

The solid top under the lathe collects lots of wood shavings and is harder to clean than vacuuming them up from the floor. The shavings also hide the tools, calipers, drills, etc. that will collect on the top of the stand.

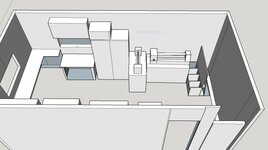

I now have the cabinet to the side of the lathe. My lathe is on a "open" metal stand so the shavings can fall to the floor. The lathe and chuck tools are stored on a rack on the wall behind the lathe. The grinder and light are on the opposite side of the lathe from the cabinet. Lights and dust/CA fume collection are also there.

Finding that it easier to clean up after turning and that I'm spending a lot less time looking for tools hidden under the wood shavings.

Just my two cents on the subject.