Knockologist

Member

Hello all. I'm still new here so apologies if there is another thread that discusses this. I was unable to find any info.

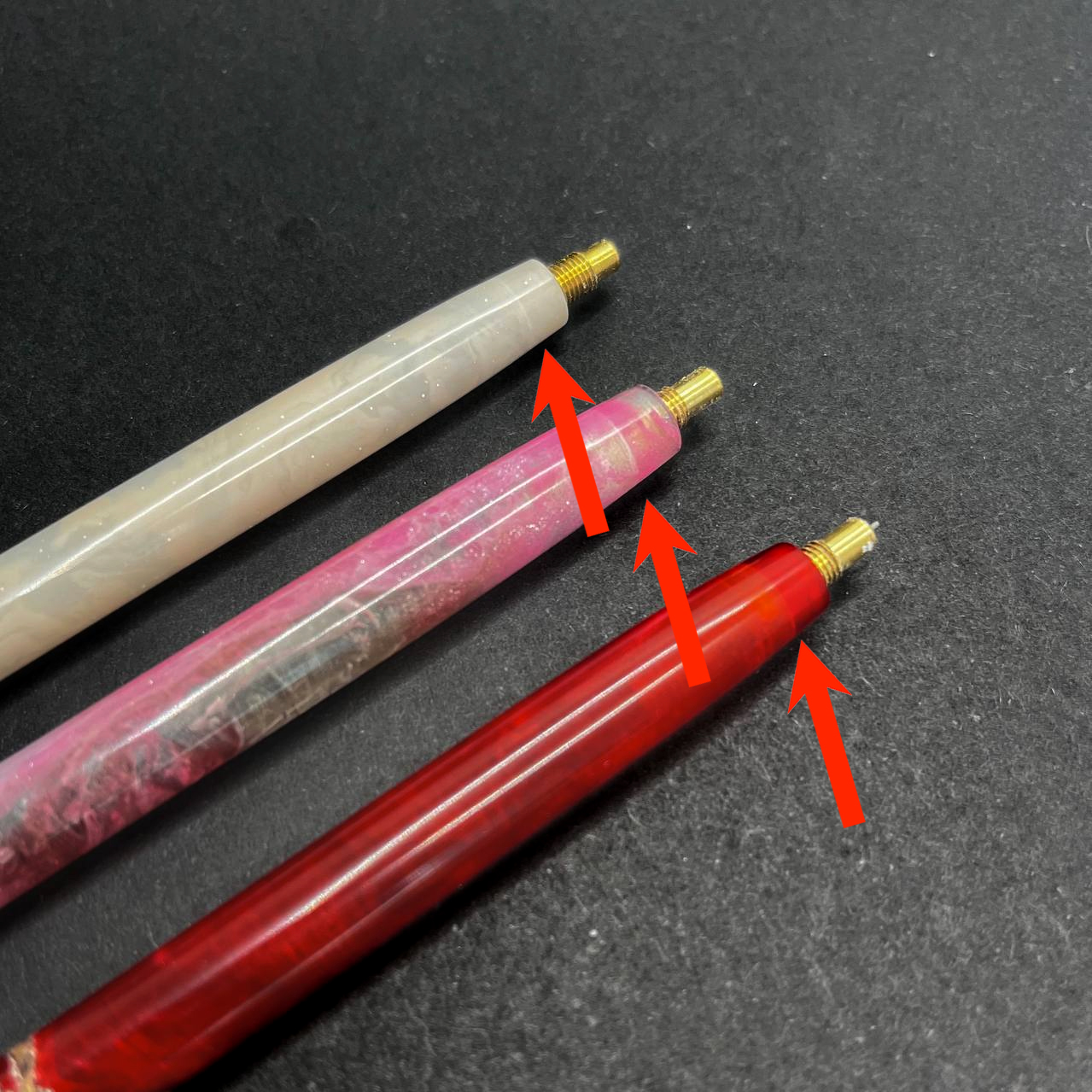

I'm making Pentel conversions and I like to make them pretty thin, like on the original Pentel P200 pieces. I've noticed that there's a bit of what appears to maybe a fractured line that shows up towards the nose end of the body where the taper goes down to the nose cone. It's hard to see but I've tried to show some examples in the picture below.

I've manually tested the strength and it appears to be strong and doesn't, at least easily, break off.

Is there anything I need to worry about with this?

Also, do any of you add the little lip that's found on the Pentel P200 barrel for the nose cone to sit in? I haven't attempted to add that lip.

I'm making Pentel conversions and I like to make them pretty thin, like on the original Pentel P200 pieces. I've noticed that there's a bit of what appears to maybe a fractured line that shows up towards the nose end of the body where the taper goes down to the nose cone. It's hard to see but I've tried to show some examples in the picture below.

I've manually tested the strength and it appears to be strong and doesn't, at least easily, break off.

Is there anything I need to worry about with this?

Also, do any of you add the little lip that's found on the Pentel P200 barrel for the nose cone to sit in? I haven't attempted to add that lip.