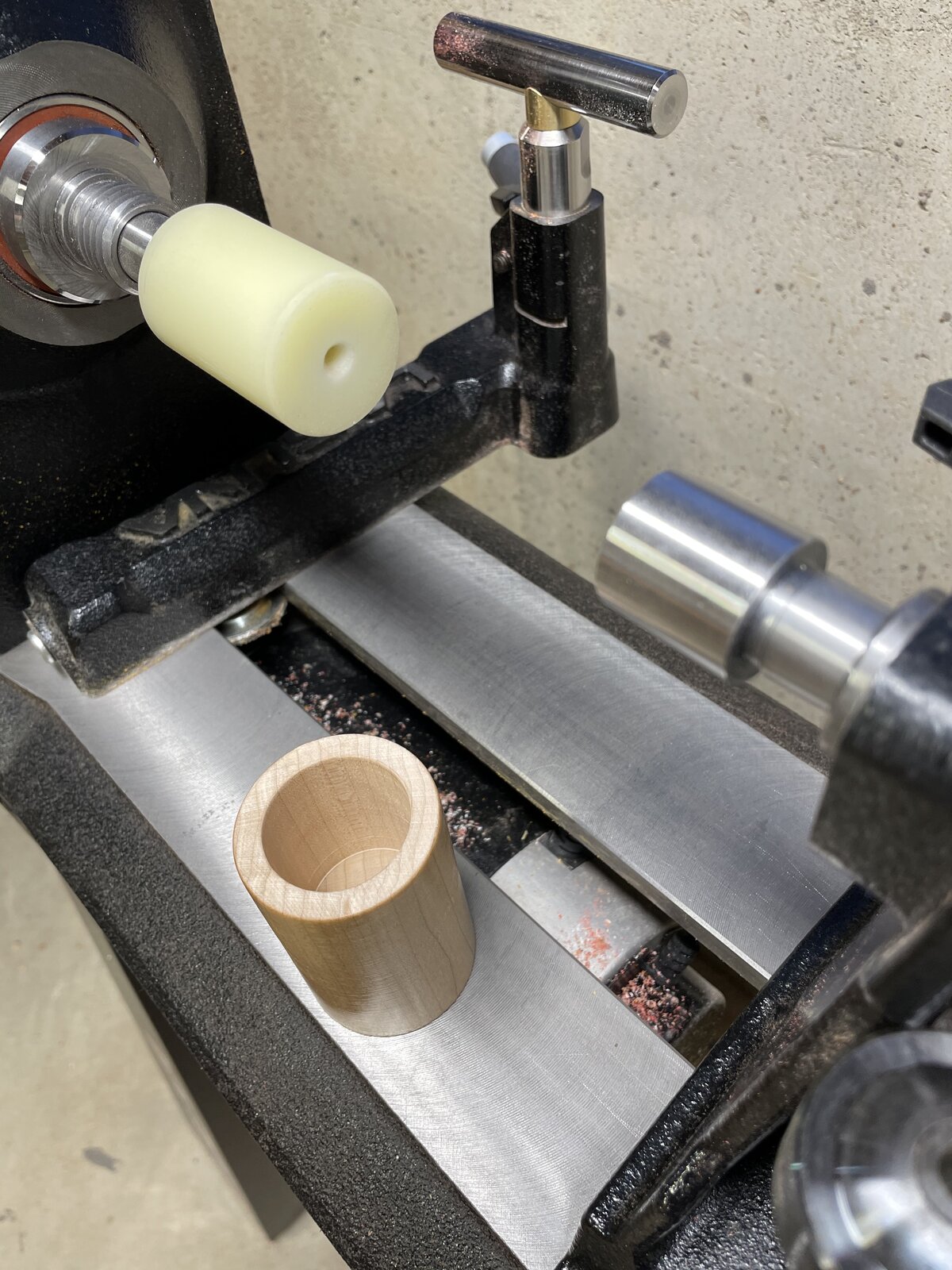

I have tried other versions of these and never liked them much. Reason being it was difficult holding everything in place while you turned the tailstock wheel. This new model eliminates all that frustration because the one end is spring loaded. That's a game changer. I love this one. Only drawback to it is the plastic part has a hole in it, intended to hold the pen nib. Sometimes that's good, sometimes it's not. My solution was to just make a hardwood sleeve that slips over it, when needed.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Pen State New Between Centers Pen Press

- Thread starter KenB259

- Start date

Signed-In Members Don't See This Ad

Signed-In Members Don't See This Ad

duncsuss

Member

I use tools I already have - drill chuck in the tailstock holding a stubby screwdriver so the handle acts as the piston, and collet chuck in the headstock holding a scrap piece of acetal that I turned - made two, one just faced-off, the other with a dimple in the middle to line up the nib.

I've never had a problem holding things aligned; I start by sliding the headstock in until there's just enough pressure to hold the parts in place, then use both hands to get it all squared up. Then hold at the coupling with my left hand while gently cranking the quill.

What I like most about this (versus a press) is that it doesn't unwind and drop all the parts when I take my hand off the wheel.

I've never had a problem holding things aligned; I start by sliding the headstock in until there's just enough pressure to hold the parts in place, then use both hands to get it all squared up. Then hold at the coupling with my left hand while gently cranking the quill.

What I like most about this (versus a press) is that it doesn't unwind and drop all the parts when I take my hand off the wheel.

carlmorrell

Member

I really like the pennstate assembly/disassembly press. Before that, I used a 4" bench vise, sometimes parallel clamps. Once I got the press, I kicked myself for not getting it sooner.

sorcerertd

Member

Yep, ditto to this. I do agree with Ken about the hole in the center, though. Not sure I like it, but there are ways around that.I really like the pennstate assembly/disassembly press. Before that, I used a 4" bench vise, sometimes parallel clamps. Once I got the press, I kicked myself for not getting it sooner.

egnald

Member

I really like the PSI Assembly/Disassembly press too and I'm on board with the whole hole thing. I swear I've had it leave some marks on some of the nibs I pressed in. As Ken has done, I made a sleeve to slip over the end with the hole, but I made mine out of HDPE. I also made a sleeve to go over the aluminum end just so I was pressing against HDPE from both sides. I've even considered making one or two special sleeves with the right sizes of recess holes. Then on some of the threaded components I can press against the shoulder of the component instead against the threads.

I rarely use my press for disassembly anymore though. I've been more successful with the PSI "Soft Jaw Barrel Gripper" clamped in my bench vise and the PSI disassembly punch set. Although the press works, it applies more of a constant force where the punch method applies a more abrupt forces by being struck by a mallet. (That and I got tired of converting my press back and forth whenever I needed to disassemble something -- which in my case seems to be far to often).

I might have to invest in this new MT2 "Between Centers Pen Press" though. I really like the idea of having the precise control afforded by cranking the tailstock over the breakaway force that must be overcome using the handle/leaver system on the pen press, especially when pressing a component to a specific depth rather than pressing it up against a hard stop.

Regards,

Dave

I rarely use my press for disassembly anymore though. I've been more successful with the PSI "Soft Jaw Barrel Gripper" clamped in my bench vise and the PSI disassembly punch set. Although the press works, it applies more of a constant force where the punch method applies a more abrupt forces by being struck by a mallet. (That and I got tired of converting my press back and forth whenever I needed to disassemble something -- which in my case seems to be far to often).

I might have to invest in this new MT2 "Between Centers Pen Press" though. I really like the idea of having the precise control afforded by cranking the tailstock over the breakaway force that must be overcome using the handle/leaver system on the pen press, especially when pressing a component to a specific depth rather than pressing it up against a hard stop.

Regards,

Dave

Last edited:

I have been very happy with it. The tail stock has virtually no slop at all. Runout at the spindle also zero. The three belt positions change very easily. Speed control works very well. It is just a very heavy duty well made lathe. I have not run into anything bad or annoying.Ken

Not to change the subject, but, How do you like the Laguna lathe.

I am thinking about getting one

mmayo

Member

You will be happy. Can you say S M O O T HKen

Not to change the subject, but, How do you like the Laguna lathe.

I am thinking about getting one

penicillin

Member

- Joined

- Feb 27, 2019

- Messages

- 1,036

I use the lathe pen press that @KenB259 does not like. This one:

https://www.woodcraft.com/products/lathe-pen-press-adapters-2-mt

I have used other pen presses, but that one is my favorite and works well for me. (I have never tried the one that Ken describes above.)

I always use the flat end without the hole for the part to be inserted. The hole seems intended for pen nibs, but if you use it that way, it may leave a dent in the pen nib.

https://www.woodcraft.com/products/lathe-pen-press-adapters-2-mt

I have used other pen presses, but that one is my favorite and works well for me. (I have never tried the one that Ken describes above.)

I always use the flat end without the hole for the part to be inserted. The hole seems intended for pen nibs, but if you use it that way, it may leave a dent in the pen nib.

Smooth is right. I can stand a dime on end on the bed and turn the lathe on wide open and the dime doesn't move a bit.You will be happy. Can you say S M O O T H

howsitwork

Member

Back to presses and I've made adaptors from HDPE a and Nylon to fit in the centre of my drill press table so I can use the drill press for insertion. Not too sure about it as yet as only tried it a couple of times. Will report back.

Not actually the one OI tried in the past, but similar.I use the lathe pen press that @KenB259 does not like. This one:

https://www.woodcraft.com/products/lathe-pen-press-adapters-2-mt

I have used other pen presses, but that one is my favorite and works well for me. (I have never tried the one that Ken describes above.)

I always use the flat end without the hole for the part to be inserted. The hole seems intended for pen nibs, but if you use it that way, it may leave a dent in the pen nib.

pturley

Member

My favorite pen press has always been a Number "0" arbor press.

A bit expensive, yes, but VERY handly to have in the workshop (automotive, woodworking, all of the above!)

A bit expensive, yes, but VERY handly to have in the workshop (automotive, woodworking, all of the above!)

I have an arbor press and I have used it as a pen press as well as a pen disassembly press. It does work and it surely does come in handy.My favorite pen press has always been a Number "0" arbor press.

A bit expensive, yes, but VERY handly to have in the workshop (automotive, woodworking, all of the above!)

howsitwork

Member

totally agree as to very hand to have . Never considered using as a pen press thoughI have an arbor press and I have used it as a pen press as well as a pen disassembly press. It does work and it surely does come in handy.

Overkill yes, but very controllable. I really like the new ones I started this thread about. I am going to make some sleeves with holes to press click pens with.totally agree as to very hand to have . Never considered using as a pen press thoughBit overkill perhaps ??

howsitwork

Member

Granted Ken it's totally controllable. Also for pen disassembly ( not an issue for you

but for we mere mortals

but for we mere mortals  ) with sleeves and bushes that could be very useful. Thanks for the idea. I made some HDPE sleeves and blocks for use in my drill press . Also over sleeves for the tailstock centre so I can push on stuff without leaving a mark. Works well in certain situations.

) with sleeves and bushes that could be very useful. Thanks for the idea. I made some HDPE sleeves and blocks for use in my drill press . Also over sleeves for the tailstock centre so I can push on stuff without leaving a mark. Works well in certain situations.

Ha, I do my share of disassemblyGranted Ken it's totally controllable. Also for pen disassembly ( not an issue for youbut for we mere mortals

) with sleeves and bushes that could be very useful. Thanks for the idea. I made some HDPE sleeves and blocks for use in my drill press . Also over sleeves for the tailstock centre so I can push on stuff without leaving a mark. Works well in certain situations.