I had posted a few days ago about my bad luck with a

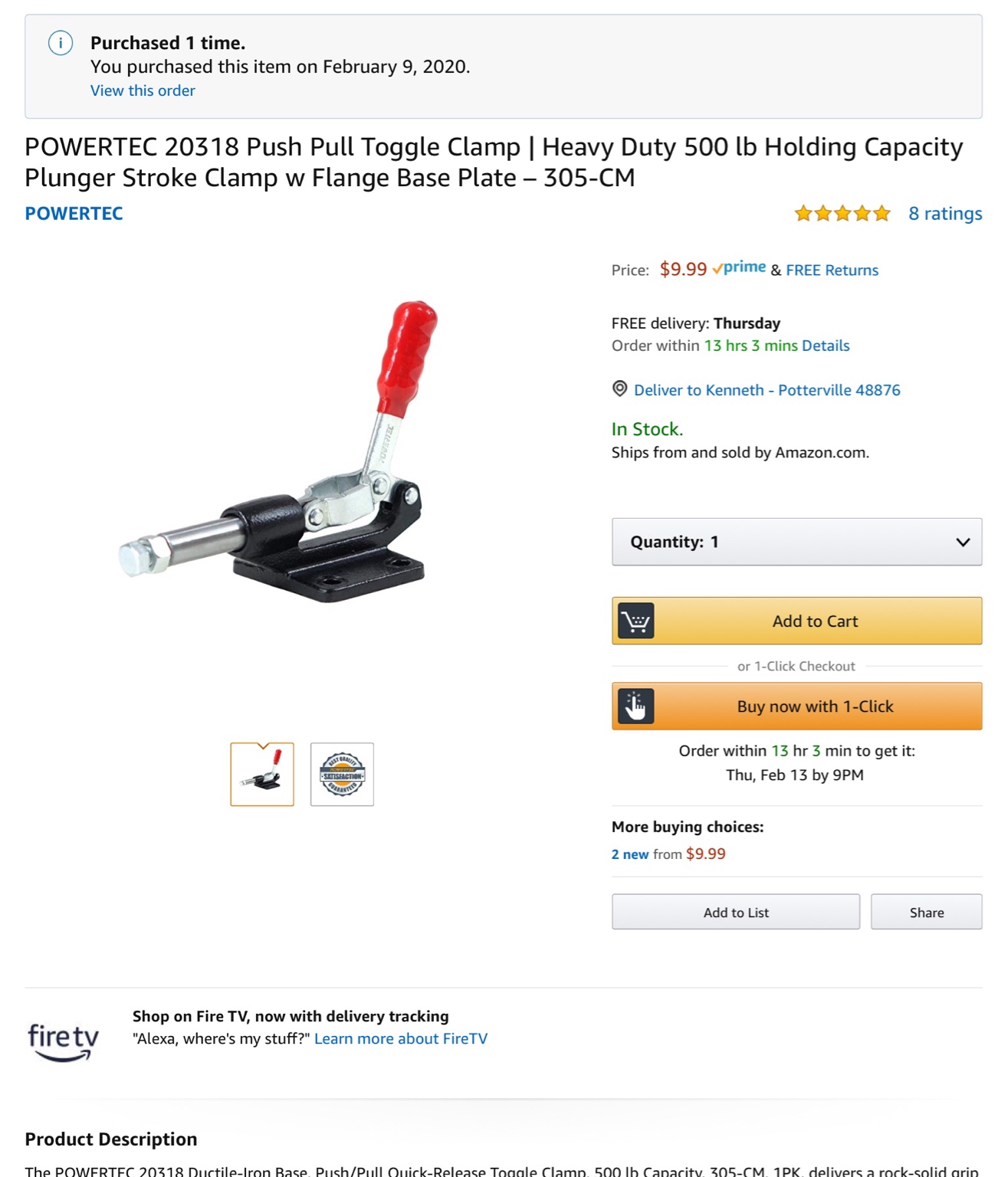

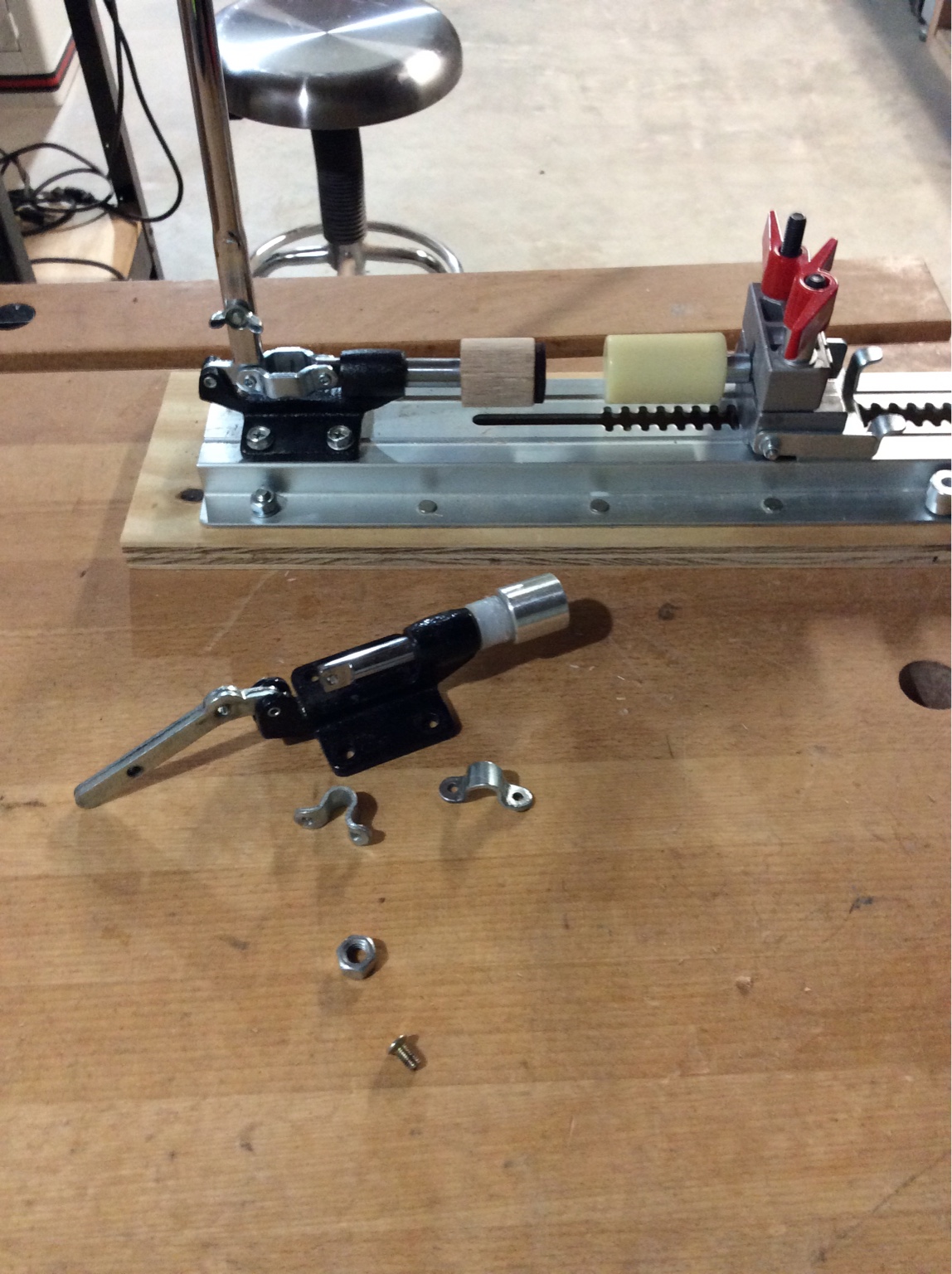

pen press that Penn state sells. My wife was feeling badly that I was not liking it much because it was a Christmas present from her. So I decided to fix it yet again, now the fourth time. This time, I decided to just replace the entire inline clamp, looked on Amazon and lo and behold looked like they had the exact one, it arrived today, here's how it went. First the bolt pattern to affix it to the press is an exact fit. I had to remove the red covering from the clamp and drill a small hole to fit a bolt through , to attach the long handle. The original one is tapped, I could have tapped the hole but I elected to just bolt it, much easier. The only small problem is the threads in the shaft is different from the original, so the original metal cylinder isn't usable. I just turned a new one from a piece of oak I had laying around and bolted it on using the bolt that came with the clamp. I inset it in and used some wood filler epoxy to make the end smooth, then just put a stick on carpet pad over it. Now the wood piece I made can just screw off and on. The best part, aside from the press is fixed and works great, is the original is rated at 250 pounds , the new clamp is rated at 500 pounds. I'm attaching a few pictures and you can see how some of the components are way more heavy duty than the original. My wife's happy as I'm no longer calling it a " POS".

pen press that Penn state sells. My wife was feeling badly that I was not liking it much because it was a Christmas present from her. So I decided to fix it yet again, now the fourth time. This time, I decided to just replace the entire inline clamp, looked on Amazon and lo and behold looked like they had the exact one, it arrived today, here's how it went. First the bolt pattern to affix it to the press is an exact fit. I had to remove the red covering from the clamp and drill a small hole to fit a bolt through , to attach the long handle. The original one is tapped, I could have tapped the hole but I elected to just bolt it, much easier. The only small problem is the threads in the shaft is different from the original, so the original metal cylinder isn't usable. I just turned a new one from a piece of oak I had laying around and bolted it on using the bolt that came with the clamp. I inset it in and used some wood filler epoxy to make the end smooth, then just put a stick on carpet pad over it. Now the wood piece I made can just screw off and on. The best part, aside from the press is fixed and works great, is the original is rated at 250 pounds , the new clamp is rated at 500 pounds. I'm attaching a few pictures and you can see how some of the components are way more heavy duty than the original. My wife's happy as I'm no longer calling it a " POS".

Sent from my iPad using Penturners.org mobile app

Sent from my iPad using Penturners.org mobile app