Ok, seriously though Brad. Would you rather have the torrent of questions here or on your site?

I am trying to setup an area for questions on there but its being troublesome at the moment.. will figure it out soon enough, though feel free to ask where you like

Here's my first couple;

I just watched the Titanium one.

Thanks for the refraction explaination. Does this mean that you could 'polish back' through some of the layers of crystal and get a cool 'oil slick' effect?

Nope, as the density of the crystal formations changes.... but you are close to "flash anodising" with the way you are thinking

il show you that cool method at a later date, I know you will like that - though its difficult to do with professional power supplies like we have as they are designed to stop it happening.

I'm sure I wasn't the only one to be very suprised by the very short time in the acid. Literaly seconds. If you leave it longer, will the colour alter?

Is the acid only reacting whilst there is current flow, because you seemed to keep it out wet without rinsing it for longer than you had it in the tank?

Correct, with the cathodes being in the tank the current can only flow through the piece when its in the tank.

Regardless to how long you leave it in th tank past this point the colour will not change. it will only change if you vary the voltage.

And lastly ( for this post anyway :biggrin: ) I'm assuming that the power supply being self modulating, makes up for varying distance you may have between anode and cathode?

Why do you use two lead plates instead of just one.?

Correct again. you will find the closer to the plates you are, the less current you will use as the path of resistance is less. we could always consult Ohms law V/IxR but we will leave that out for now hey? :tongue:

I use multiple plates for a couple of reasons. electricity is lazy.. it will always take the shortest route so to ensure an even process i like the plates to surround the piece. this is more prominent with odd shaped items. if it was an oblong shape, im siure you can see that the voltage flowing through the end closest to the plates will be much greater than the other end of the oblong furthest away.

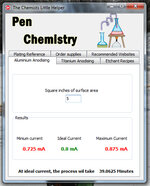

Secondly, when anodising the siurface area of the cathodes should be twice the size of the anode. all of that cathode surface area of the two plates gives me plenty of headroom for larger items or multiple pen pieces etc. remember that the inside of the pen counts as surface area too, not just the exterior of the piece being anodised.

Just one final one.......please can my local church have it's flashing back? The roof is leaking !!:biggrin:

Lol around here to combat this they replaced the stolen lead with a fake lead which holds no value so isnt worth stealing. the trouble is, it looks the same :biggrin: so they are still nicking it lmfao... er didn't quite think that one through did they.

I'm signing up too Brad. Now you'll have at least three of the IAP Riff-Raff wanna be scientific followers bugging you. :biggrin:

lol Chuck thats what the sites for