keithkarl2007

Member

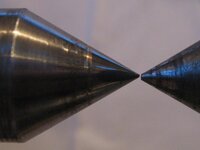

I got a new axminster variable speed lathe over 2 months ago and have only started using it as i was waiting for pen mills and other stuff to arrive. I purchased a dead centre, live centre and bushings from JohnnyCNC hoping it would make life a little less painful but i'm still having trouble turning out of round. I just don't know what the problem is. I've tried going back to the mandrel and thats worse. It has me really frustrated as I've bought a load of pen kits and blanks in the past few months. Any ideas???