Aces-High

Member

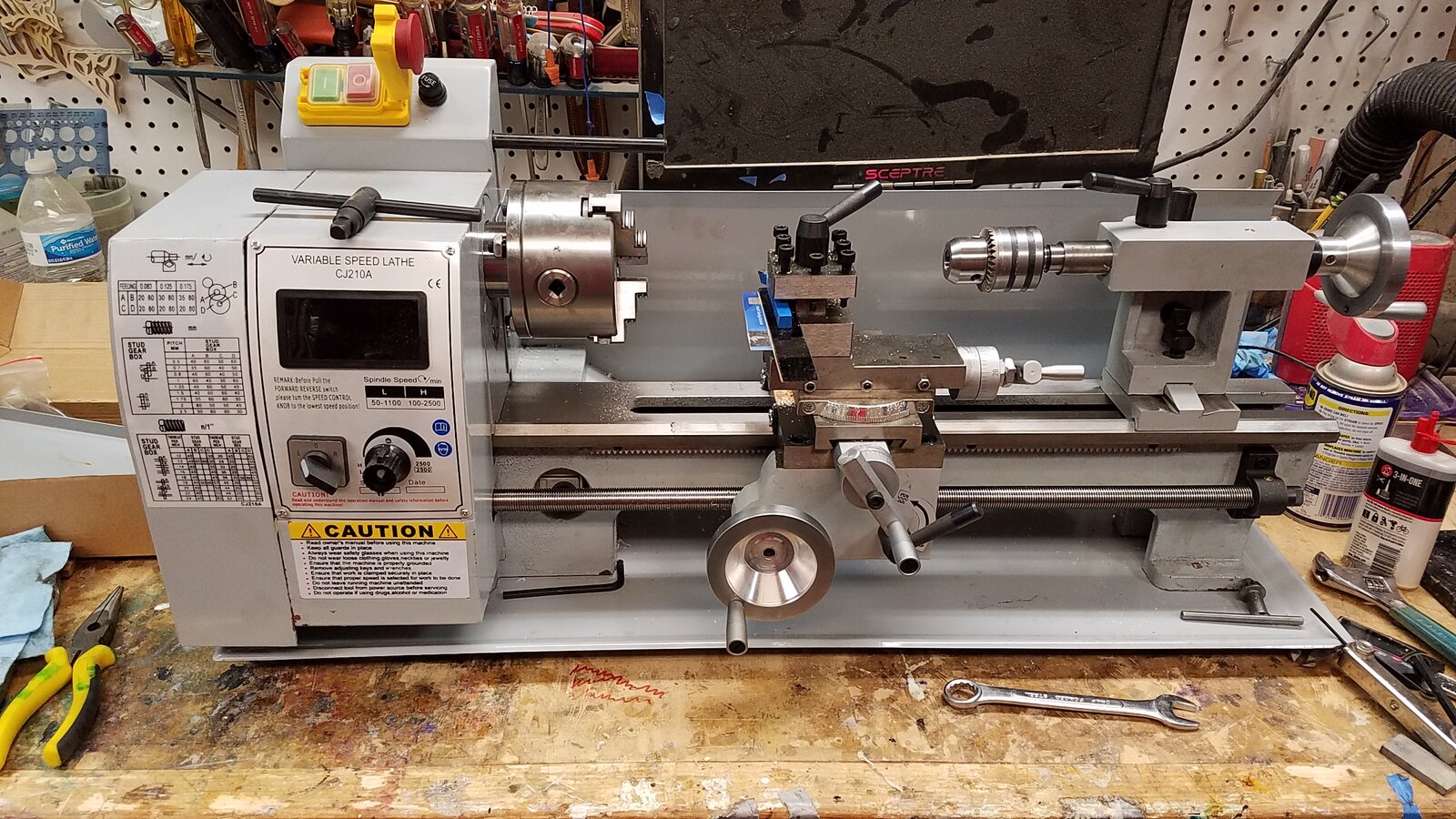

Picked this up my local Craig's list for $350. Any suggestions for the basics I will need for kitless would be appreciated.

Jason

Jason

Curiosity had me looking around and all I could find were "bulk" buy sites. One site I saw would sell them at $600 ea but had to purchase 3.Looks like you got a good deal. How much does one of those run new?

Do you have a good way of getting the cutting tool up to center? When I square the end it leaves a bump. I have just been using scrap segmenting bits to get it up.Congratulations !! . That lathe is in VERY good condition and I would unreservedly say that you got a bargain.

This lathe looks like it is probably a Sieg lathe (no name on outside, but probably on the printed circuit board inside).

Looks like it has a 3-jaw 4" chuck. ... That is very good, but a 4-jaw 4" chuck could be better ... keep it in mind for the future.

I have had my Sieg for over 10 years and it is still going strong.

First thing you need will be a couple of carbide cutting tools.

Contact .... rherrell .... (username on IAP) and ask him to make for you.

I recommend a round cutting tool (11 mm round cutter) on a 5/16" square "rod" holder (most suitable for the tool post on your lathe, I would think, but 3/8" might also work). . I have been using such a cutting tool made by him for 10 yrs. . The 11 mm round cutters can be bought from Global Tooling and I have ordered from them ( rherrell might not have any in stock). . I have been extremely happy with these. . They stay sharp almost forever.

So that will get you "doing something".

I do NOT recommend the triangular cutters that you can buy from general machine tool suppliers. . I think I see one of these (blue) on your lathe now.

One other thing you will need .... right from the start .... is a live center for the tailstock.

Soon you will find useful a "live" Jacobs chuck for the tailstock.

Start browsing the .... LittleMachineShop.com .... website.

Oh, couple of other things you will need are ... extra tool post and tool holders ... be careful what you buy cuz not all will fit ... plus parting tool blade

Contact me if you want to know more.

Do you have a good way of getting the cutting tool up to center? When I square the end it leaves a bump. I have just been using scrap segmenting bits to get it up.

I have no idea what a "rule" is.One way is to keep facing the end and raising the cutter until the nub is gone. Another way is to put a steel rule against the diameter of the stock and slide your tool against the rule. If the rule slants then you are off center. Adjust until the rule is perpendicular to the lathe bed.

Sent from my iPhone using Penturners.org mobile app

The guy I bought it from said he paid around $700 for it, used it once and is now moving and didn't want it.Curiosity had me looking around and all I could find were "bulk" buy sites. One site I saw would sell them at $600 ea but had to purchase 3.

A rule is a metal ruler. Machinist rules are steel. On one side they are stamped or laser etched in traditional increments, 16th, 32nds, 64ths. On the other side the are etched in tens; not to be confused with a tenth, which is 1 10,000th of an inch, but rather 1, 10th of an inch and then also down to 1, 100rdth of an inch. They are for rough measurements only. Otherwise you would use a dial caliper for most things, or a micrometer for super accuracy. Machinist measurements are typically 1 - 1000th. For example 1/4 of an inch would be 250ths (250, 1000ths (.250)). Tenths are much smaller. In pen making, there is no need to be accurate to a tenth, in fact most Chinese lathes are only accurate down to 3 thou (3 thousandths of an inch) or less than the width of a human hair.I have no idea what a "rule" is.

This "should" be the tool post set you need. This is what I got for my grizzly 7x14I would appreciate any sites you guys buy this stuff from as well.

I have no idea what a "rule" is.

I'm sure you wont have any issues getting rid of it. People are desperate to find old iron like this. Depending on the features, etc., you could be looking at getting over 1k if you sell it.Cool. I really need to use my metal lathe, or get rid of it. It is a South Bend 9" that I inherited from my grandfather, and used as a wood lathe until I got my real wood lathes. It is as big as a volkswagon and takes up a huge hunk of room.

Other desirable bits are a taper turning attachment ( on the back of the bed ) , milling vertical slide and a quick change tool post.a volkswagon

The main reason that I recommended a 4-inch 4-jaw chuck is to get the throat diameter that you need to "swallow" round blanks of up to about 0.85" diameter for squaring the ends and for drilling. . What I had in mind was a 4-jaw self-centering. . A 4-inch 3-jaw would also serve but the 4-jaw could arguably give you more flexibility. . I often rely on the 4 jaws as convenient indicators of angular position ( 4 x 90 degrees ) rather than "mucking" around with the 3 jaws ( 3 x 120 degrees ).

I personally do not have any use (that I know of) for a 4-jaw independent, although I can fully understand the need for such if you are, for example, facing some irregularly shaped flatwork piece. . Could be useful also, for example, in drilling a hole during the fabrication of a clip before it is bent.

But that latter job can be done with a self-centering chuck also if the preceding preparation has been done.

Bear in mind that getting a 4-jaw independent set up accurately can be a "bear" of a job until you become adept at it.

I think your mounting plate "should " have the appropriate bolt pattern in it for any 4" chuck. Best way to find out would be to remove the chuck from the mounting plate and see what holes you have in it.I know that the independent is harder, but I have other reasons as well for getting it.

My overall question was about fitting the new chuck to my lathe. Will all 4" chucks fit without an adapter? It came with a 4", I think I may have said 3" before.

The main reason that I recommended a 4-inch 4-jaw chuck is to get the throat diameter that you need to "swallow" round blanks of up to about 0.85" diameter for squaring the ends and for drilling. . What I had in mind was a 4-jaw self-centering. . A 4-inch 3-jaw would also serve but the 4-jaw could arguably give you more flexibility. . I often rely on the 4 jaws as convenient indicators of angular position ( 4 x 90 degrees ) rather than "mucking" around with the 3 jaws ( 3 x 120 degrees ).

I personally do not have any use (that I know of) for a 4-jaw independent, although I can fully understand the need for such if you are, for example, facing some irregularly shaped flatwork piece. . Could be useful also, for example, in drilling a hole during the fabrication of a clip before it is bent.

But that latter job can be done with a self-centering chuck also if the preceding preparation has been done.

Bear in mind that getting a 4-jaw independent set up accurately can be a "bear" of a job until you become adept at it.