fitzman163

Member

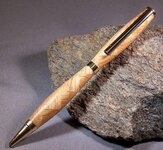

I have a customer that wanted an Oak Majestic jr. wish I tried to talk him out of (Oak). With all the beautiful wood out there, thats another issue. When sanding it the sanding dust gets in the pours and crackes of the wood and turns them very dark. It looks as if the blank was under a pile of dirt. Any suggestions on how to prevent this and or clean up the mess I already have would be greatly appreciated. I tried CA finish I havn't been sucessful with that. I used Mylands friction polish 4 coats it looked very nice and then I put it to the buffer. That was a big mistake the grain filled up with the Tripoli and it was down hill from there.