rherrell

Member

I wanted to quiet down my lathe a little so I searched for some nylon gears that would fit. No luck, my gears are a Module 1.25mm and nobody had any.

So, I decided to make my own and after waiting 3 weeks for the cutter to arrive I got to work.

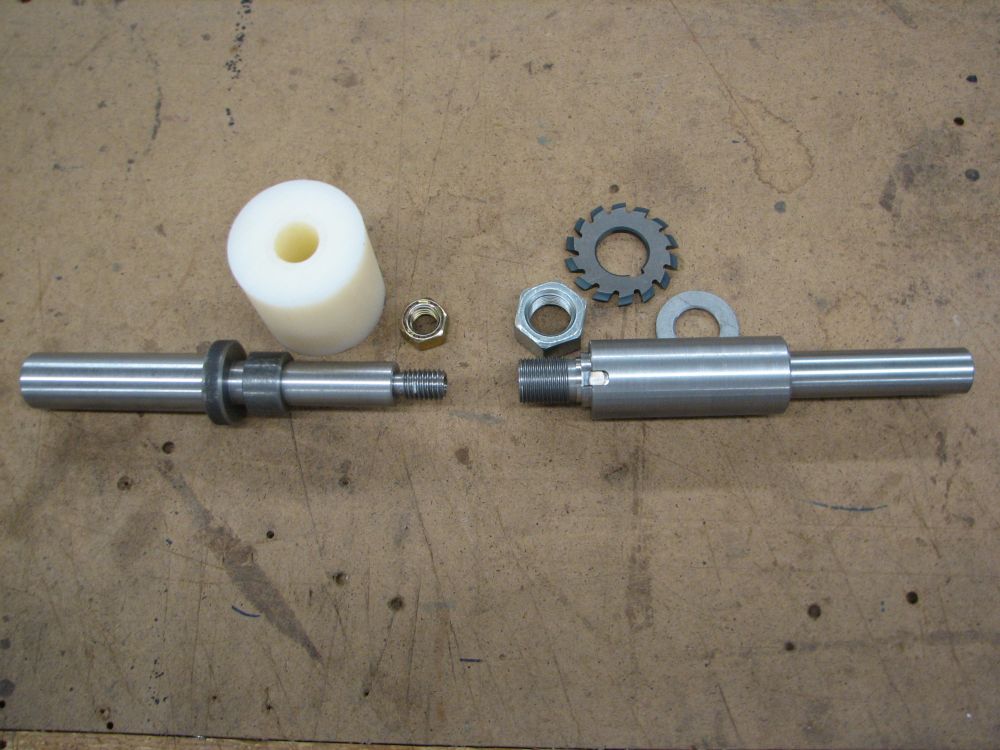

First thing to do was to make two mandrels, one to hold the nylon and the other for the gear cutter...

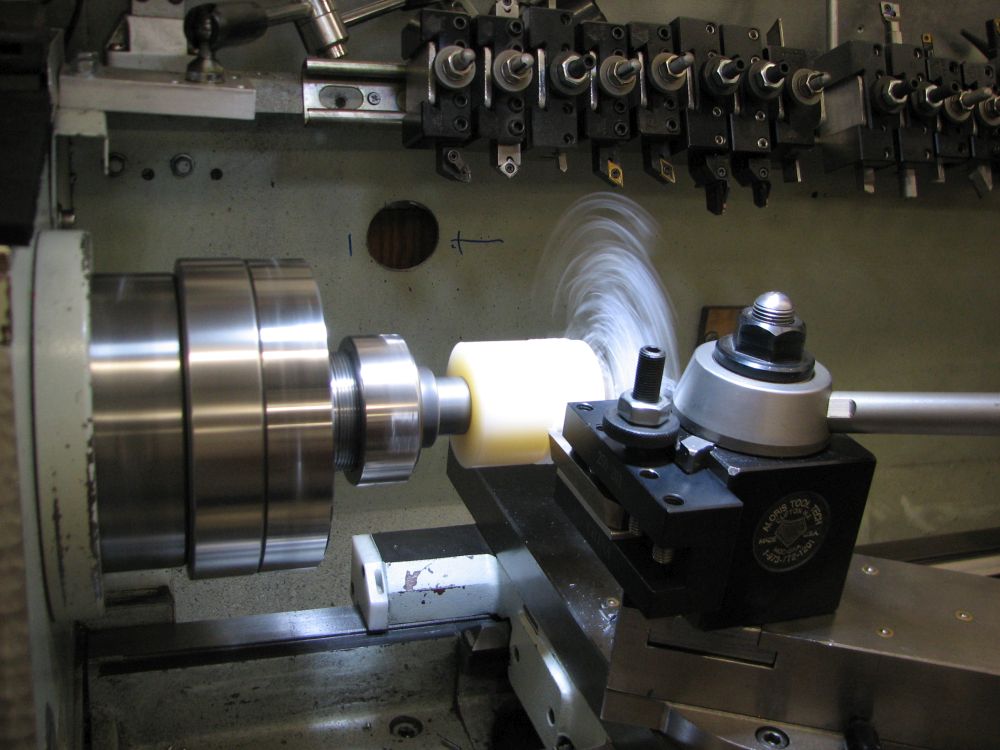

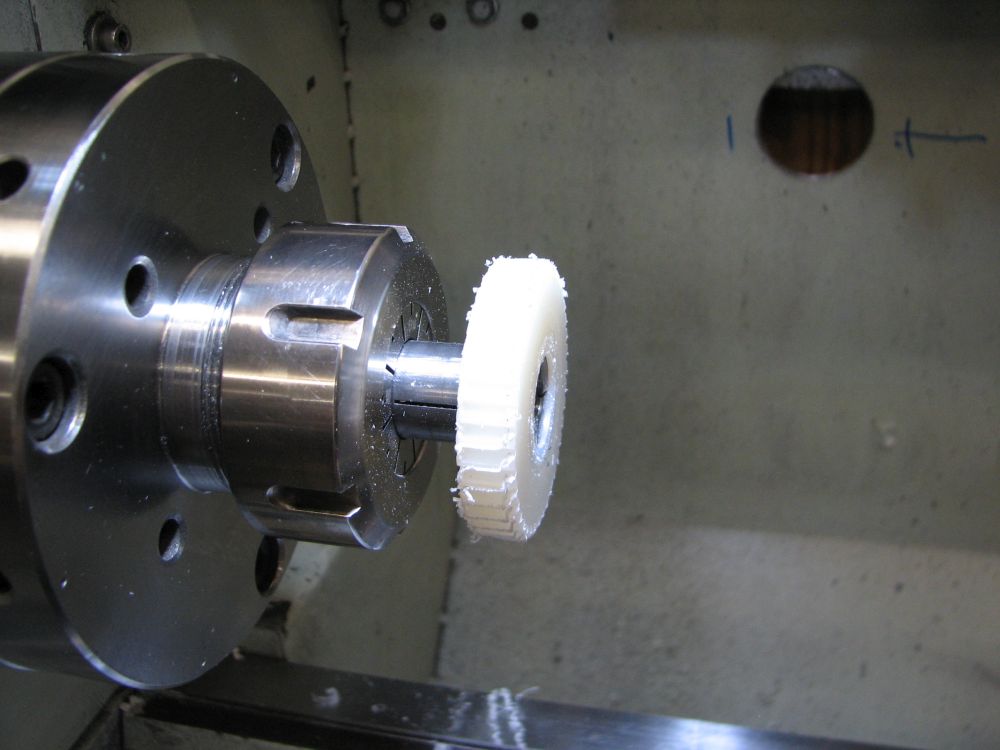

Next step was turning the nylon to size...

Stringy stuff!!!

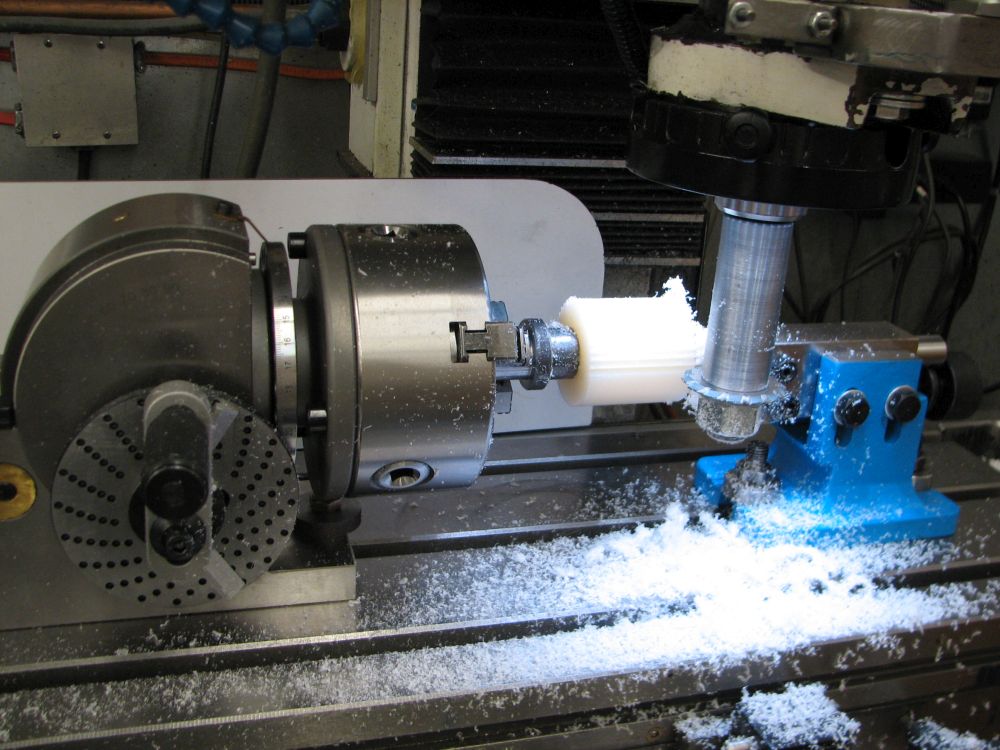

Next step, cutting the gear teeth...

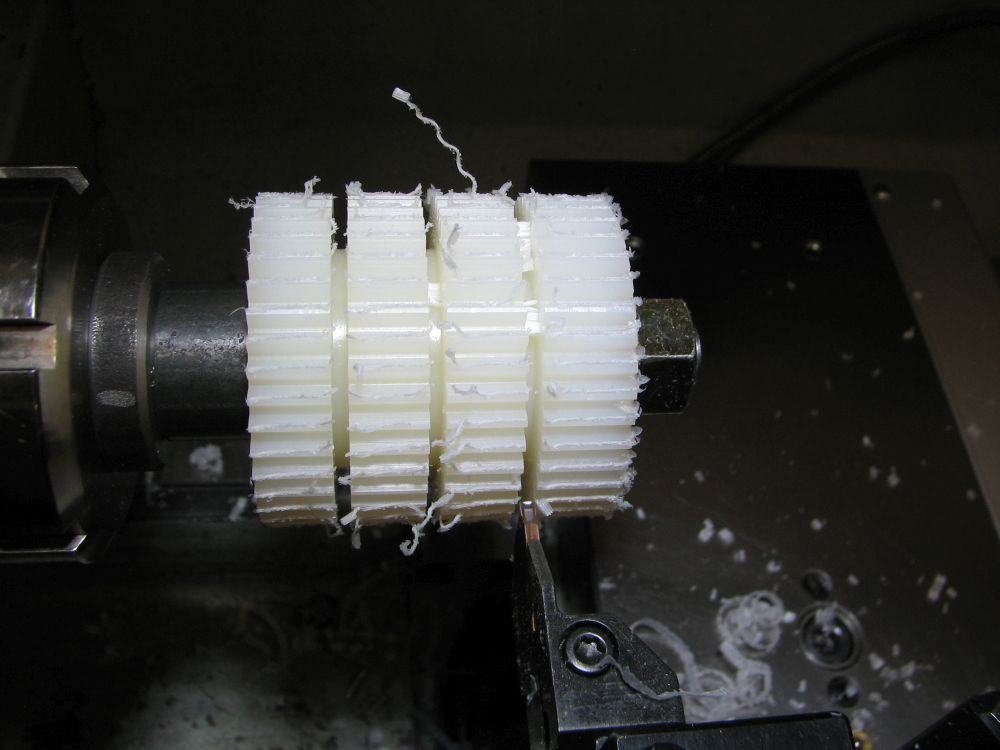

Next I parted the blank into four pieces...

Then I modified one of my expanding mandrels so I could clean up the outside of all four gears..

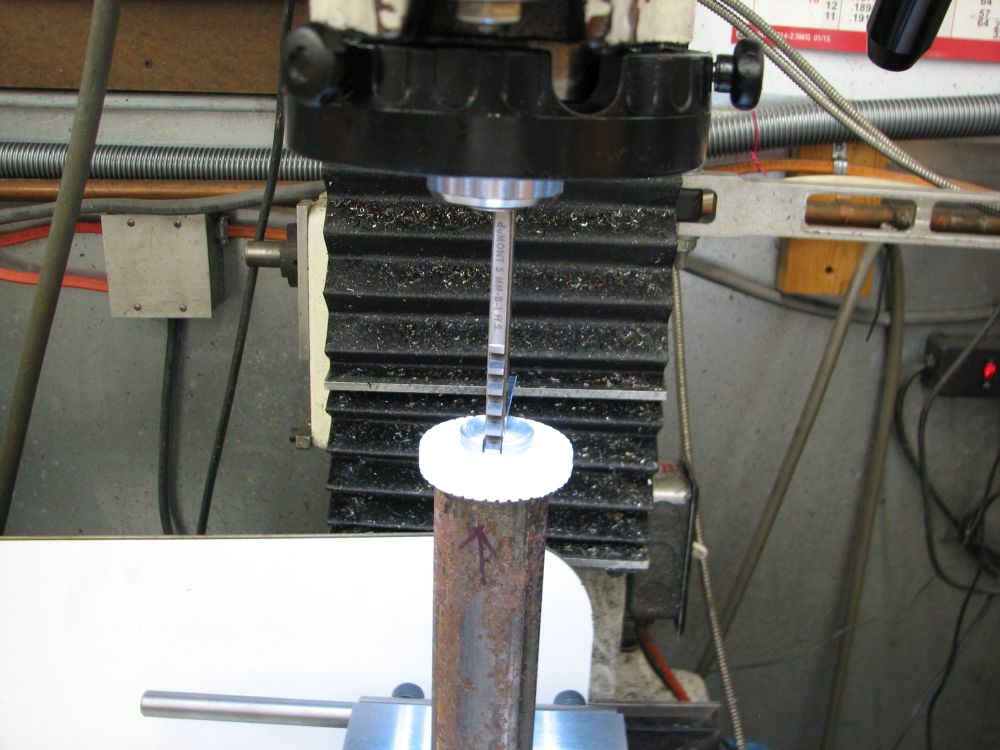

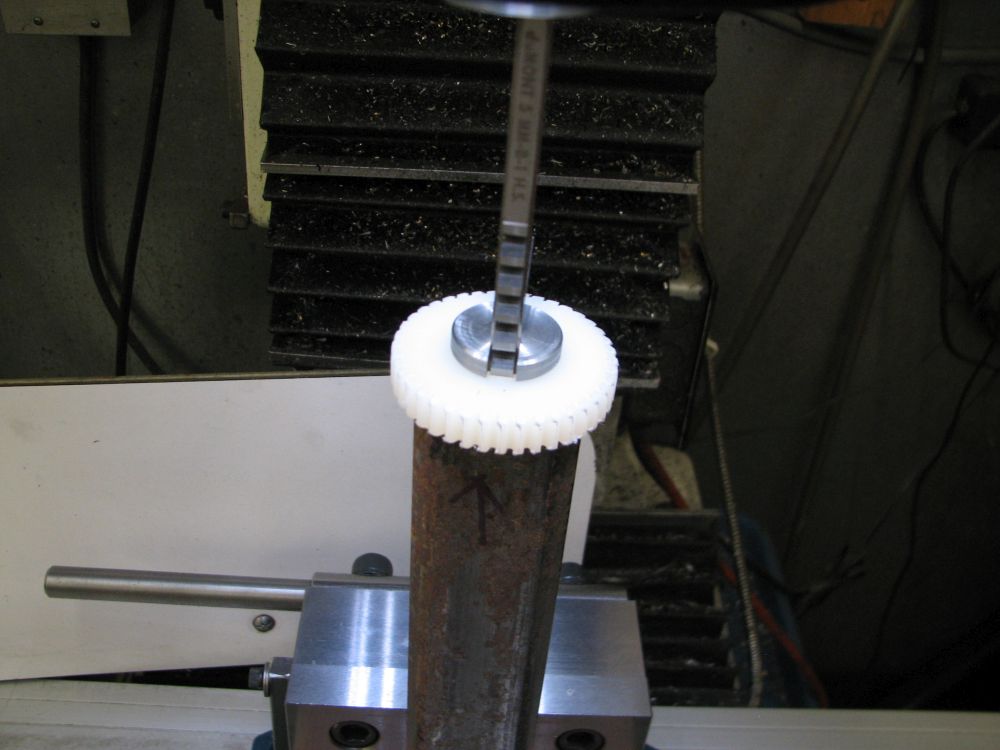

Now it was time to broach the keyway slot, I used my mill as a press and since this was nylon it worked well. Not something I would do on a steel gear...

Here are the four nylon gears along with the steel ones they replaced. I'm keeping two for spares...

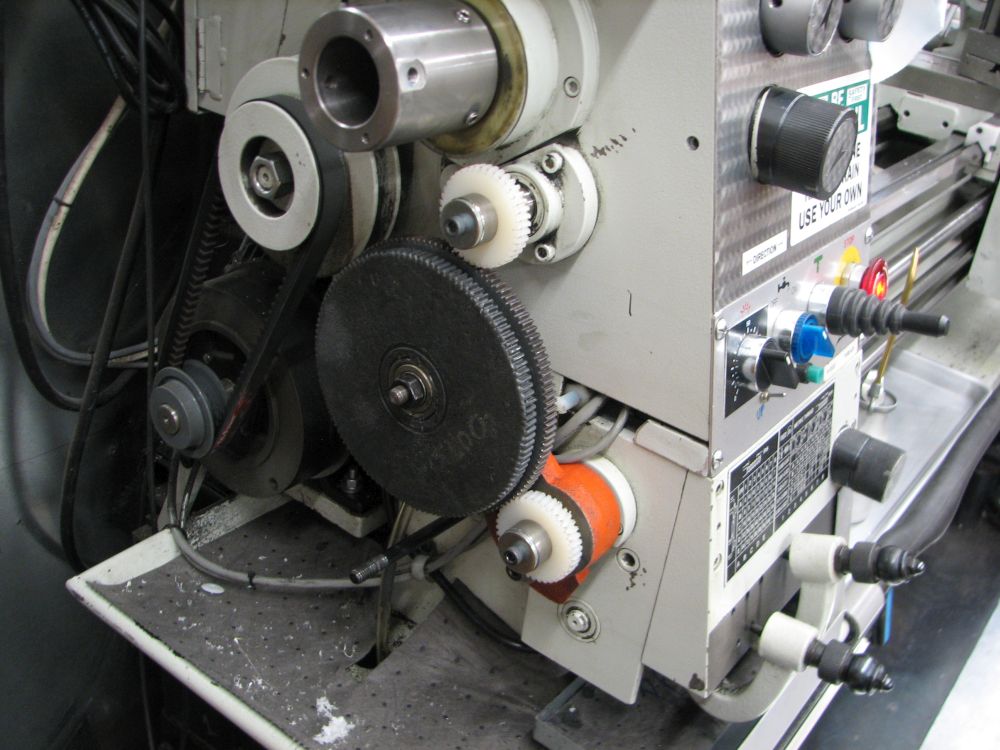

And finally, here they are installed on my lathe...

The big main gear remains steel.

I'm REALLY happy with the outcome, it made a SIGNIFICANT difference in the loudness of my lathe!!!

Thanks for looking!

So, I decided to make my own and after waiting 3 weeks for the cutter to arrive I got to work.

First thing to do was to make two mandrels, one to hold the nylon and the other for the gear cutter...

Next step was turning the nylon to size...

Stringy stuff!!!

Next step, cutting the gear teeth...

Next I parted the blank into four pieces...

Then I modified one of my expanding mandrels so I could clean up the outside of all four gears..

Now it was time to broach the keyway slot, I used my mill as a press and since this was nylon it worked well. Not something I would do on a steel gear...

Here are the four nylon gears along with the steel ones they replaced. I'm keeping two for spares...

And finally, here they are installed on my lathe...

The big main gear remains steel.

I'm REALLY happy with the outcome, it made a SIGNIFICANT difference in the loudness of my lathe!!!

Thanks for looking!