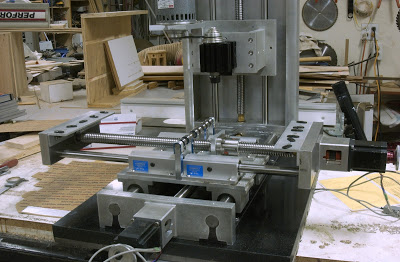

I realize this is pretty far out there as the category "other things we make" goes but this has kept me busy amoungst the other projects I'm working on for the last month or so. I have a small Taig cnc mill but decided I needed something a little more ridged and larger. So I used the Taig to cut the parts needed to build this one.

The side rails are 27 inches tall and the bottom rails are 24inches long. It will have a work area it will cut in at about 9x12.5. and 12 inches tall. The Taig is a great machine but it has its limits and I have hit them. Some of the cutters I use are .010 of a mm. (.003) I built this with a supported roller bar underneath the mill spindle that I will shim to support the work table after everything is Trammed.

Because I used 27in long 80/20 extruded aluminum rails for the table I wanted to make sure it wouldn't sag in the center under the cutter. The side rails that support the work table are 24in apart.

I have plumbed and squared everything to within .005 that I could. Now it is time to take out a Dial indicator and start the final lock down trying to get it within .0005. the Ball screws will give me zero back lash. and I still need to add grease zerks to the linear bearings. I'm having a controller built and it should be here in a week. it uses a 1 hp Ac/dc 10,000 rpm motor to drive the spindle. All in all its been a great challenge and a fun project. My Taig mill will only cut 11.5 inches in the x direction and the side rails for the z column are 27 inches long. I had to cut and slide and cut and slide each rail it took about a day apiece to cut the rails. They are within .0025 over 27inches.

Hope you enjoyed looking.

Mike

The side rails are 27 inches tall and the bottom rails are 24inches long. It will have a work area it will cut in at about 9x12.5. and 12 inches tall. The Taig is a great machine but it has its limits and I have hit them. Some of the cutters I use are .010 of a mm. (.003) I built this with a supported roller bar underneath the mill spindle that I will shim to support the work table after everything is Trammed.

Because I used 27in long 80/20 extruded aluminum rails for the table I wanted to make sure it wouldn't sag in the center under the cutter. The side rails that support the work table are 24in apart.

I have plumbed and squared everything to within .005 that I could. Now it is time to take out a Dial indicator and start the final lock down trying to get it within .0005. the Ball screws will give me zero back lash. and I still need to add grease zerks to the linear bearings. I'm having a controller built and it should be here in a week. it uses a 1 hp Ac/dc 10,000 rpm motor to drive the spindle. All in all its been a great challenge and a fun project. My Taig mill will only cut 11.5 inches in the x direction and the side rails for the z column are 27 inches long. I had to cut and slide and cut and slide each rail it took about a day apiece to cut the rails. They are within .0025 over 27inches.

Hope you enjoyed looking.

Mike