OKLAHOMAN

Member

About a week ago I received an E-mail from Martin Beauford (mhbeauford) asking if I would like to turn a blank that he made and maybe consider marketing them. Never since Eagle have I had my hiney pucker when turning a blank:wink:.

These are not for the novice, beginner, or faint of heart but for the person who is looking for a challenge and a higher end pen.

Steps must be followed to achieve a final product. I recommend drilling on the lathe sloooooow, do not get the blank hot no more than .25 at a time and clean out the flues after drilling, drizzle CA into the hole and let sit overnight, now re drill to clean out excess CA. Mill on your sander NOT with a pen mill!

Use as light a touch as possible and have a scary sharp skew, or tool of your choice. You might even want to use your 100 grit skew:wink: to take down to almost finished diameter.

Click photos for larger view

These are not for the novice, beginner, or faint of heart but for the person who is looking for a challenge and a higher end pen.

Steps must be followed to achieve a final product. I recommend drilling on the lathe sloooooow, do not get the blank hot no more than .25 at a time and clean out the flues after drilling, drizzle CA into the hole and let sit overnight, now re drill to clean out excess CA. Mill on your sander NOT with a pen mill!

Use as light a touch as possible and have a scary sharp skew, or tool of your choice. You might even want to use your 100 grit skew:wink: to take down to almost finished diameter.

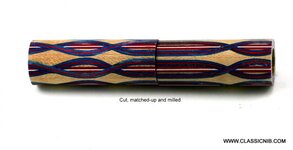

Martin used card stock as inlay material and the white is styrene, all inlays are .25 deep leaving a .25 solid core, the base wood is hard maple