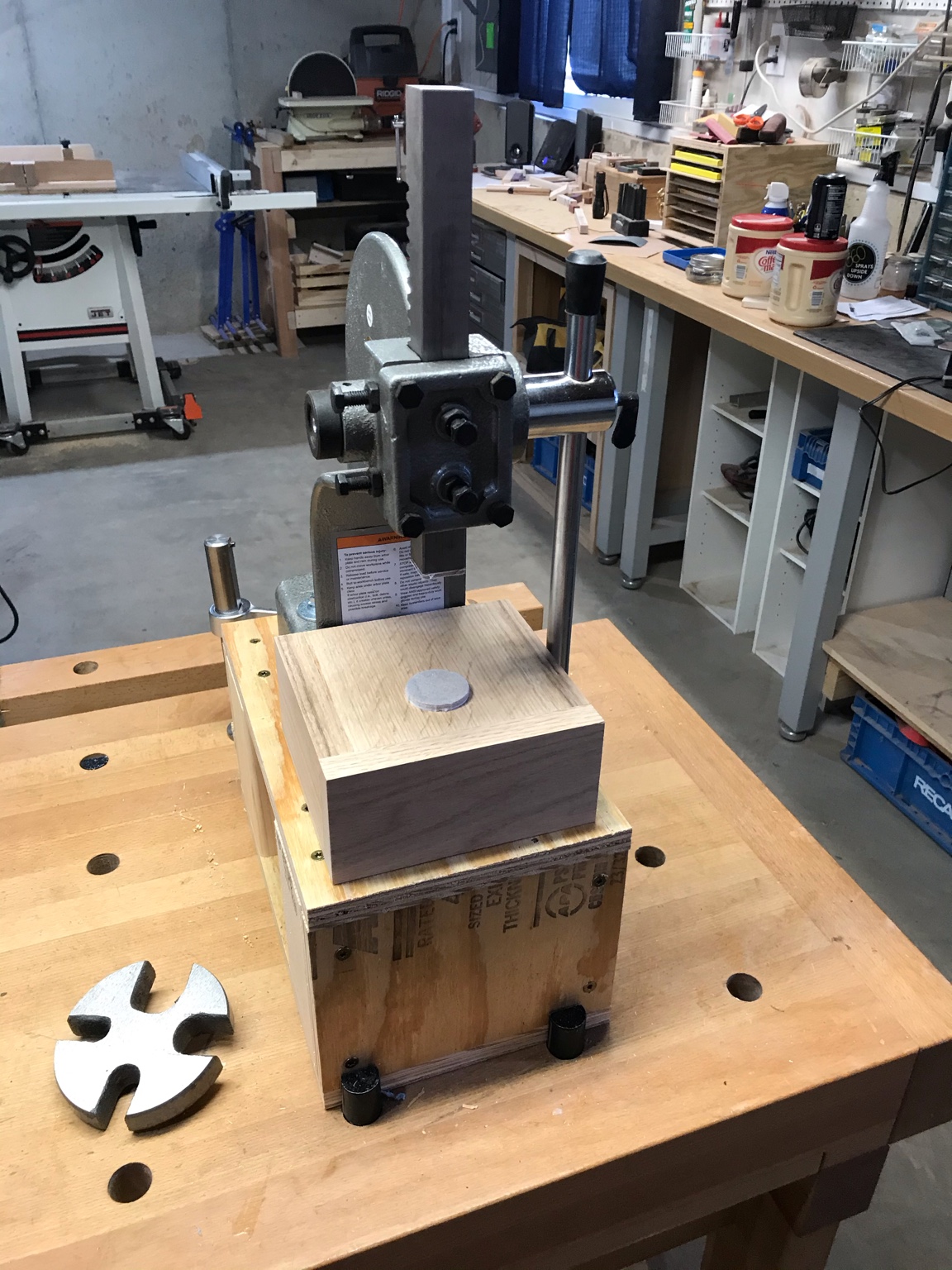

My wife bought me a new pen press for Christmas, a pretty well know one. Well since Christmas, I have broken it 3 times. Before that I had just used my lathe and pressed pens together between the head and tail stock. It worked fine, and whether there's any truth to it or not, I always felt it might not be the best for my lathe. I have always been a believer in using tools as their intended use. I decided to just go ahead and adapt an arbor press that I already had. I just made a little table that can slide on and off, attached some stick on pads to the plunger and the table, to protect the pen components. I also built it up a little bit so it's at eye level when sitting at my bench.

Sent from my iPhone using Penturners.org mobile app

Sent from my iPhone using Penturners.org mobile app