sorcerertd

Member

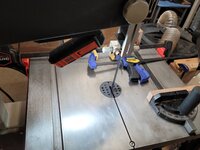

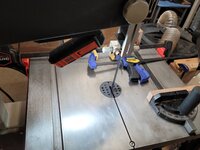

I got an upgrade to my cheap tabletop bandsaw (it was a small hobby saw, not good for much). It's a 12" Craftsman (made by Rikon), 3/4 hp. The table is solid and good sized. I put it through some paces today cutting up some stuff I've had drying for a couple years. I now have a lot of spalted maple blanks. The box elder looks like it really needs to be cast into hybrids, but I'm still not ready to make that investment just yet.

The dust collection leaves a bit to be desired with just using the 4" port. I think I need to split that and connect to both the 2.5" and the 4". Also, why don't manufacturers make inserts that sit flush with the table top? Geez. My table saw was the same way, but a couple washers fixed that.

The dust collection leaves a bit to be desired with just using the 4" port. I think I need to split that and connect to both the 2.5" and the 4". Also, why don't manufacturers make inserts that sit flush with the table top? Geez. My table saw was the same way, but a couple washers fixed that.