Todd in PA

Member

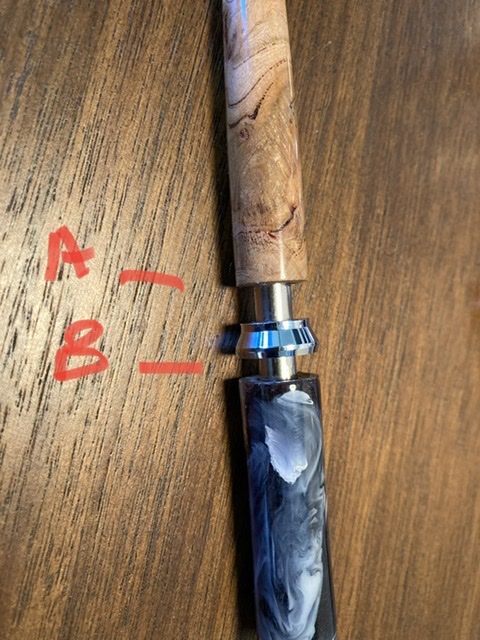

Here is my latest pen.

I like it but it has two problems.

I like it but it has two problems.

1.) It is out of round at the nib. I've read about out of round and this is the first time I've experienced it. Could someone explain what causes it, exactly. Is it somewhat preventable by taking more care with centering my bushings. I usually just slide everything on the mandrel and snug it up. It is going to have to happen more than one or two times out of 40 for me to dispense with the bushings and TBC. But I'll take advice and follow instructions if I need to adopt this new practice.

2.) The band is loose. All of my bands are loose, so this is not a new problem with this pen. I read here that if I don't like the band spinning and rattling, I can CA it to one of the barrels. But I'm not clear which one— if it matters. It seems likely that some glue will come out or get inside and adhere to the transmission. A or B?

1.) It is out of round at the nib. I've read about out of round and this is the first time I've experienced it. Could someone explain what causes it, exactly. Is it somewhat preventable by taking more care with centering my bushings. I usually just slide everything on the mandrel and snug it up. It is going to have to happen more than one or two times out of 40 for me to dispense with the bushings and TBC. But I'll take advice and follow instructions if I need to adopt this new practice.

2.) The band is loose. All of my bands are loose, so this is not a new problem with this pen. I read here that if I don't like the band spinning and rattling, I can CA it to one of the barrels. But I'm not clear which one— if it matters. It seems likely that some glue will come out or get inside and adhere to the transmission. A or B?

Last edited: