dpstudios

Member

Well. I did it, bit the bullet, pulled the trigger, shot my w... you get the idea. I purchased a new metal lathe. I have gone down yet another rabbit hole pursuing this thing we calll turnng, pens or other things.

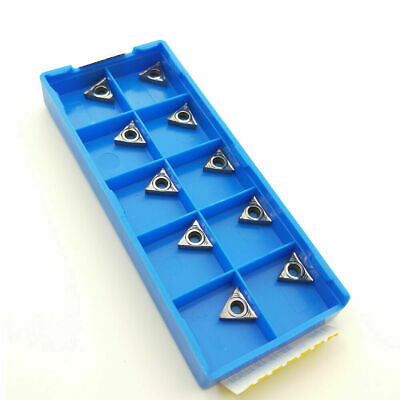

Picked the one I saw on Ebay as the best deal I could find for what I could afford. Ordered Monday and arrived today. I expected a large, beat up cardboard box. Nope, a (well, not quite a crate) plywood box. Inside the machine is bolted to the bottom and Styrofoam inserts hold the lathe in place. I'd already opened it up when I decided to take pics, hence the torn plastic cover. Included is a toolbox with wrenches, allen and open ended, metal change gears, 2 screwdrivers, outside jaws, 5 carbide cutting tools, and what I would guess is an oil bottle . I also expected it to be covered in grease. Just a light film of oil covers everything. Still in the box for now until the stand arrives Saturday. All in all it seems to be a well built and substantial

The next couple of weeks will be practice, practice, practice until I get a feel for turning on this mini beast. Should be fun.

Picked the one I saw on Ebay as the best deal I could find for what I could afford. Ordered Monday and arrived today. I expected a large, beat up cardboard box. Nope, a (well, not quite a crate) plywood box. Inside the machine is bolted to the bottom and Styrofoam inserts hold the lathe in place. I'd already opened it up when I decided to take pics, hence the torn plastic cover. Included is a toolbox with wrenches, allen and open ended, metal change gears, 2 screwdrivers, outside jaws, 5 carbide cutting tools, and what I would guess is an oil bottle . I also expected it to be covered in grease. Just a light film of oil covers everything. Still in the box for now until the stand arrives Saturday. All in all it seems to be a well built and substantial

The next couple of weeks will be practice, practice, practice until I get a feel for turning on this mini beast. Should be fun.