JGordon

Member

Hi All!

I'm brand new to the family and the hobby. I've been turning like a maniac for just over a year-and-a-half and just recently dove head-first into pens. I know there's been many discussions about squaring the blanks to the tubes - using end mills, sanders, Rick Herrell's offset jig (a very nice looking piece of kit!), and other lathe-mounted options.

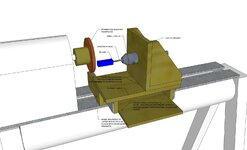

Not to take away from any of the other solutions, but I decided to make my own sanding jig for the lathe. It consists of a base with magnets that fits onto the lathe bed. I used two 8" drawer slides to create a table that slides back and forth perpendicular from the centerline of the lathe, with a support panel that keeps the slides tracking evenly and square. On this table I mounted a series of gussets drilled and tapered to accept my keyless drill chuck, trying my best to keep everything as square as possible. I mounted a homemade faceplate with PSA sandpaper to the headstock. Now I can mount my centering punch in the drill chuck, slide the blank on, and move the table in and out to take advantage of the entire width of the sandpaper. Granted, I had to do a bit of shimming and tweaking to the chuck mount to ensure everything was as square as possible to the sanding faceplate, but so far everything is working better than I'd hoped. The chuck fits nice and snug with a couple of taps using my mallet, and comes out just as easy by tapping the exposed end of the MT3 shaft.

Now it only takes minutes to true up a batch of blanks. I grab the sled, place it on the lathe, insert the right sized punch into the chuck, and sand the blank. Moving the sled back-and-forth is smooth and it allows for frequent checks on the blank to see my progress. So far, most blanks will "sing" a different note the moment the sandpaper hits the brass tube, so I haven't had any issues with over-trimming. I keep a small brass brush on the sled and use it to clean the sandpaper often. All of the blanks have made a very nice fit to the hardware and I haven't found anything that I would change (so far!).

Anyway, I've attached a SketchUp version of the sled (I haven't photographed the actual sled yet). Seems like a relatively cheap and cheerful solution. Thanks for listening!!

I'm brand new to the family and the hobby. I've been turning like a maniac for just over a year-and-a-half and just recently dove head-first into pens. I know there's been many discussions about squaring the blanks to the tubes - using end mills, sanders, Rick Herrell's offset jig (a very nice looking piece of kit!), and other lathe-mounted options.

Not to take away from any of the other solutions, but I decided to make my own sanding jig for the lathe. It consists of a base with magnets that fits onto the lathe bed. I used two 8" drawer slides to create a table that slides back and forth perpendicular from the centerline of the lathe, with a support panel that keeps the slides tracking evenly and square. On this table I mounted a series of gussets drilled and tapered to accept my keyless drill chuck, trying my best to keep everything as square as possible. I mounted a homemade faceplate with PSA sandpaper to the headstock. Now I can mount my centering punch in the drill chuck, slide the blank on, and move the table in and out to take advantage of the entire width of the sandpaper. Granted, I had to do a bit of shimming and tweaking to the chuck mount to ensure everything was as square as possible to the sanding faceplate, but so far everything is working better than I'd hoped. The chuck fits nice and snug with a couple of taps using my mallet, and comes out just as easy by tapping the exposed end of the MT3 shaft.

Now it only takes minutes to true up a batch of blanks. I grab the sled, place it on the lathe, insert the right sized punch into the chuck, and sand the blank. Moving the sled back-and-forth is smooth and it allows for frequent checks on the blank to see my progress. So far, most blanks will "sing" a different note the moment the sandpaper hits the brass tube, so I haven't had any issues with over-trimming. I keep a small brass brush on the sled and use it to clean the sandpaper often. All of the blanks have made a very nice fit to the hardware and I haven't found anything that I would change (so far!).

Anyway, I've attached a SketchUp version of the sled (I haven't photographed the actual sled yet). Seems like a relatively cheap and cheerful solution. Thanks for listening!!