ProSingulisArts

Member

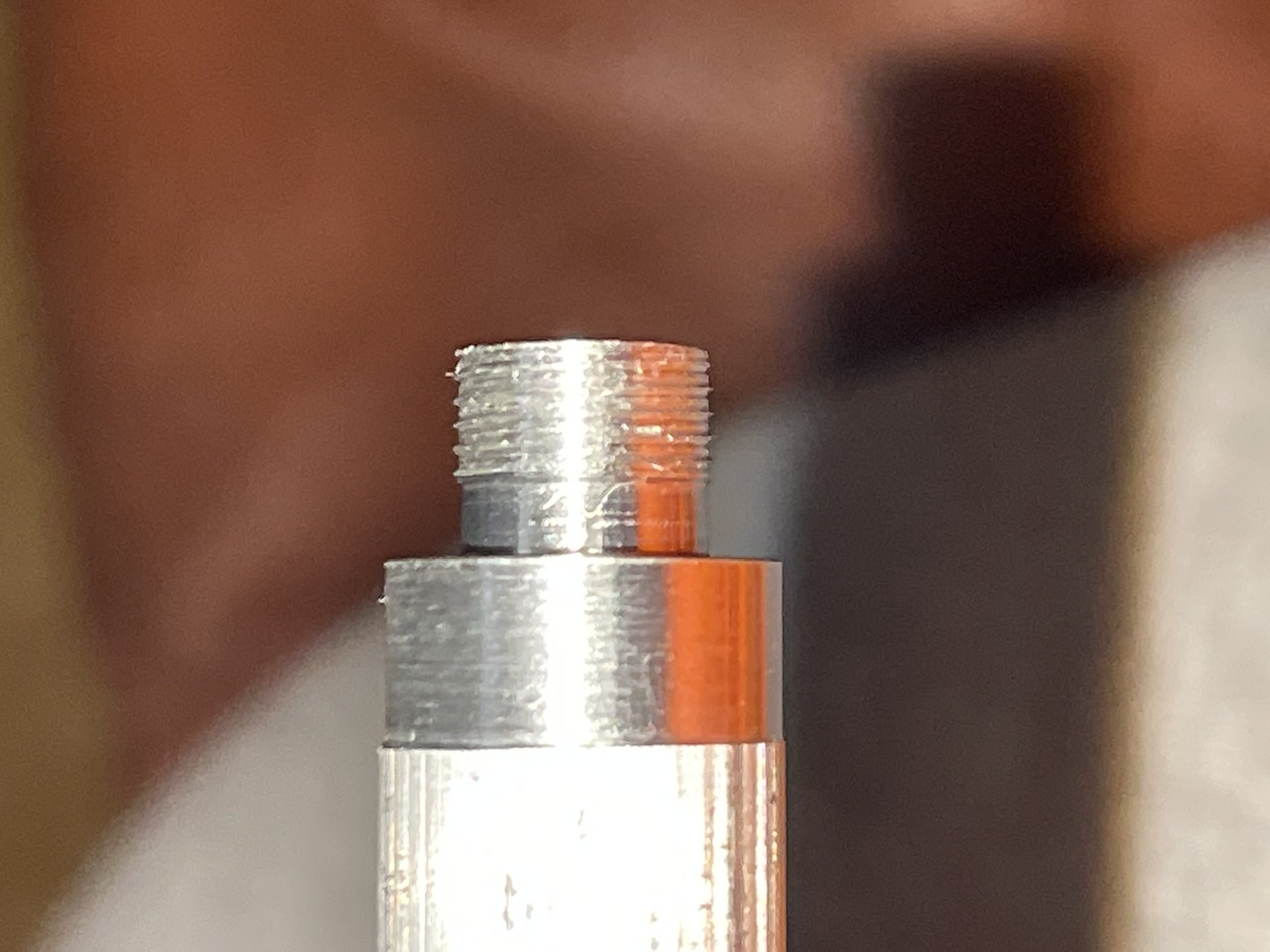

Hello all! I am just getting started with taps and dies for pen making. I thought I'd start simple and make a mandrel for making a finial. I'm practicing on .5" aluminum rod. I am using an M9x0.75 single start die. I cut the tenon to 9mm OD. Threaded on the lathe with a die holder. Ran it down markings facing the work, flipped the die and ran it down again. The major diameter on my thread came out at a final 8.25mm which seems undersized by about .6mm. Is there something I'm not doing correctly? I'm also wondering about the die. It appears the threads are relieved on both sides of the die, so, I'm not sure how I would run threads clear to the shoulder with that being the case. Please help me figure this out or direct me to some info on proper technique. Thanks!

Taking a closer look, I'm wondering if I got the die started correctly when I flipped it. The threads almost have an "every other thread" look close up.

Taking a closer look, I'm wondering if I got the die started correctly when I flipped it. The threads almost have an "every other thread" look close up.

Last edited: