Although it sounds good and sometimes you get lucky, putting a tube in from the other side, especially in a slim pen isn't a great idea. You have slop inside the hole and can not guarantee the tubes line up inside. It's a virtual guarantee you will end up with an out of round pen or a bent pen where the upper and lower barrel do not go straight across. And then there is a second issue..the upper tube, if this is the barrel being repaired, then the tube also activates the tranny which will get stuck, maybe not push in all the way or some other problem could occur, like sticking in a file to try and clean the inside of the tubes where they join which may result in the tube being too big inside to grip the tranny...the whole thing is just a problem waiting to reveal itself. In less time than that, you could just heat the tube up and pull it out and glue in a new one...totally eliminating any future issues.

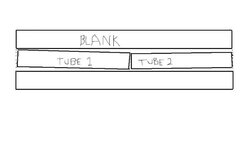

This is my picture of just stuffing tubes together into a pen blank. It's crude and exaggerated, but you get the idea. We don't make pens like this do we? I know I have more pride in my work than that. Even if you get super lucky and get a perfect mate with the tube set doing this, can you live with the inside of the pen being bastardized..or is it just the outside appearance that matters in life?