This is only my second batch of stabilizing pen blanks with cactus juice, so take all of this with a grain of salt. I figured I would post my method and data in case anyone might be interested.

I dried the blanks in a toaster oven between 200 and 220 degF for 36 hours. Cooled in ziploc bag for a few hours. Placed in vacuum chamber (pickle jar) and pulled vacuum for about 5 hours. I was able to get down close to 30 inHg (according to my "economy" oil filled gauge). There was still some bubbles coming off, but very minimal (my first batch had more bubbles coming off after 16 hrs of vacuum due to wood not being totally dry). I soaked them for about 15 hours. Wrapped in foil and then cured in the toaster oven at 200 for about 4 hours. I pulled them out and cleaned the excess resin with a sander.

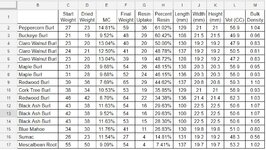

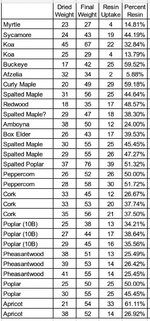

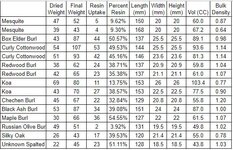

Here is my data that I collected along the way. All weights are in grams (my scale is a kitchen scale, probably could have used better precision, but its what I had...). Most interesting is the sumac, for as light as it is it didn't hardly pick up any resin. I'm happy with how much the redwood took up, as well as the black ash, since they both started out pretty dense. Everything else was basically about what I expected.

I dried the blanks in a toaster oven between 200 and 220 degF for 36 hours. Cooled in ziploc bag for a few hours. Placed in vacuum chamber (pickle jar) and pulled vacuum for about 5 hours. I was able to get down close to 30 inHg (according to my "economy" oil filled gauge). There was still some bubbles coming off, but very minimal (my first batch had more bubbles coming off after 16 hrs of vacuum due to wood not being totally dry). I soaked them for about 15 hours. Wrapped in foil and then cured in the toaster oven at 200 for about 4 hours. I pulled them out and cleaned the excess resin with a sander.

Here is my data that I collected along the way. All weights are in grams (my scale is a kitchen scale, probably could have used better precision, but its what I had...). Most interesting is the sumac, for as light as it is it didn't hardly pick up any resin. I'm happy with how much the redwood took up, as well as the black ash, since they both started out pretty dense. Everything else was basically about what I expected.