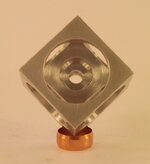

I decided that I'd had enough practice on my metal lathe to attempt a turners cube. Supposedly, it's a right of passage challenge given to old school machinists to show they can set up and use a lathe properly. The end result can look pretty cool if done well. This is probably the most simple version and if you look on-line there are many seriously complex versions.

Anyway....I could have made a clamping fixture to hold it in my 3 jaw chuck, but decided to fit my 4 jaw self centering chuck. Unfortunately it was about 0.5mm out of true, so I had to endure the pucker factor of taking my machine up to warp factor 6 and grind the jaw faces with my dremel. I'm pleased to say it is now about only 0.03mm out at about 150mm from the chuck. :biggrin:

I simply marked each face with a black marker and took dozens and dozens of extremely light passes till they were all clean of the marker.:wink:

The cube is about 35mm square which I hacksawed from a big chunk. It was squared and bored completely on the lathe.

I think this may be my new Posh Pen Pic Prop....:biggrin:

A great fun little project !! Has anyone else with a metal lathe had a go making one yet?

I don't have DRO on any part of my lathe ( except revs ) so I had to fully trust in the dials. A great exercise. :biggrin:

A great exercise. :biggrin:

Anyway....I could have made a clamping fixture to hold it in my 3 jaw chuck, but decided to fit my 4 jaw self centering chuck. Unfortunately it was about 0.5mm out of true, so I had to endure the pucker factor of taking my machine up to warp factor 6 and grind the jaw faces with my dremel. I'm pleased to say it is now about only 0.03mm out at about 150mm from the chuck. :biggrin:

I simply marked each face with a black marker and took dozens and dozens of extremely light passes till they were all clean of the marker.:wink:

The cube is about 35mm square which I hacksawed from a big chunk. It was squared and bored completely on the lathe.

I think this may be my new Posh Pen Pic Prop....:biggrin:

A great fun little project !! Has anyone else with a metal lathe had a go making one yet?

I don't have DRO on any part of my lathe ( except revs ) so I had to fully trust in the dials.