KMCloonan

Member

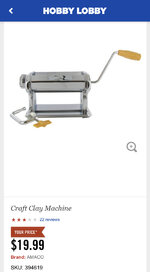

After watching numerous YouTube videos, I decided to jump into the polymer clay pool. Warning: This pool only has a deep end... The last time I worked with clay was when I was a little kid with Play-Doh, and all I remember about it was that it was salty (I tried to eat a lot of things in my formative years).

Anyway, working with polymer clay is different than anything I have done before, but I am looking forward to trying a variety of techniques I have seen, encouraged by my first attempt. Thanks to Ken (@KenB259) for some great tips and advice.

Anyway, working with polymer clay is different than anything I have done before, but I am looking forward to trying a variety of techniques I have seen, encouraged by my first attempt. Thanks to Ken (@KenB259) for some great tips and advice.