Haynie

Member

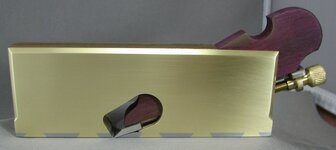

A few months ago I was looking at a wooden plane and thought that would look hot surrounded by brass and or stainless steel. I thought I was on to something new. Goes to show you how limited my world is. Then I found planes by Holtey and others who sell their infill planes for "HOLY POOP!!!" prices.

I still want to make one but I want to go all out and make the blade too.

I know there are some knife makers out there who have made their blades and gone through the process. How hard is the blade making process and what tools are seriously necessary?

I still want to make one but I want to go all out and make the blade too.

I know there are some knife makers out there who have made their blades and gone through the process. How hard is the blade making process and what tools are seriously necessary?