Dan_F

Member

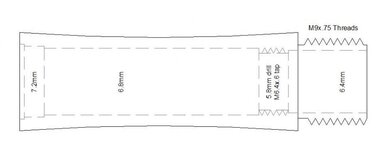

Using the triple start 12mm cap threads, is it ok to use the M9 X .75 tap and die for section threads with a #6 nib? I thought so, but ran across a thread in this forum that said that wouldn't work for the larger nib.

I have used El Grande sections (10x 1), but now want to make my own section using Meister Nib #6 assemblies, and thinking that the smaller tap and die would provide a little more security in the tenon that the cap screw on to.

What has been your experience? Thanks much.

Dan

I have used El Grande sections (10x 1), but now want to make my own section using Meister Nib #6 assemblies, and thinking that the smaller tap and die would provide a little more security in the tenon that the cap screw on to.

What has been your experience? Thanks much.

Dan