Dale Allen

Member

First off let me say this is not an exact setup and not high precision measurements. My eyes and tools are not that precise.

The lathe is a 32" HF with a rotatable head and there is a known .002" run-out in the headstock. Those 2 things alone eliminate the precision.

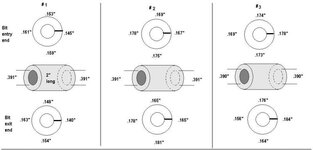

Anyway, I have been trying to adjust this thing to get the best entry-to-exit hole alignment. It has been OK, but could have been better. In the images to follow, setup #1 is what I have been using so I started from there.

I concluded that the grain in the wood can have a profound effect on the travel of the drill bit because the plastic blank ended up being the most precise. Also, I believe that the drill bit will flex to some degree and follow the hole being drilled. I say this because in those cases where the hole is not centered front to back, the exit hole was not excessively larger.

During my typical process in the past, I brought the centers together and whacked the corner of the headstock with a rubber hammer if it needed alignment of the points. Not a very exacting mechanical adjustment to say the least.

For this test I drilled 10mm holes in 5 wood blanks 2" long, then in a 3.5" wood blank and finally into a 2" PR blank that I made about 3 months ago. Measurements were taken at the entry and corresponding exit holes at 4 points. Then the holes in both ends were measured.

I use a 'not that expensive' pin jaw set and a 13mm drill chuck. After each adjustment of the headstock and tailstock, the 60 degree centers were aligned before putting in the setup for drilling.

As noted in the drawing below, the tailstock has a lot of play side-to-side so I used that as part of the tests to vary the setup.

What I wanted to see is if there was a noticeable change in the measurements as I made changes to the 'Y' axis of the drill bit and blank.

In the end, the plastic blank was within my runout error and I now believe that is the best this rig will do.

The results of the longer wood blank are not so good.

I now can check the overlap at a one corner of the headstock and then set the 60 degree points to alignment.

This will give me a more consistent setup....hopefully!

The lathe is a 32" HF with a rotatable head and there is a known .002" run-out in the headstock. Those 2 things alone eliminate the precision.

Anyway, I have been trying to adjust this thing to get the best entry-to-exit hole alignment. It has been OK, but could have been better. In the images to follow, setup #1 is what I have been using so I started from there.

I concluded that the grain in the wood can have a profound effect on the travel of the drill bit because the plastic blank ended up being the most precise. Also, I believe that the drill bit will flex to some degree and follow the hole being drilled. I say this because in those cases where the hole is not centered front to back, the exit hole was not excessively larger.

During my typical process in the past, I brought the centers together and whacked the corner of the headstock with a rubber hammer if it needed alignment of the points. Not a very exacting mechanical adjustment to say the least.

For this test I drilled 10mm holes in 5 wood blanks 2" long, then in a 3.5" wood blank and finally into a 2" PR blank that I made about 3 months ago. Measurements were taken at the entry and corresponding exit holes at 4 points. Then the holes in both ends were measured.

I use a 'not that expensive' pin jaw set and a 13mm drill chuck. After each adjustment of the headstock and tailstock, the 60 degree centers were aligned before putting in the setup for drilling.

As noted in the drawing below, the tailstock has a lot of play side-to-side so I used that as part of the tests to vary the setup.

What I wanted to see is if there was a noticeable change in the measurements as I made changes to the 'Y' axis of the drill bit and blank.

In the end, the plastic blank was within my runout error and I now believe that is the best this rig will do.

The results of the longer wood blank are not so good.

I now can check the overlap at a one corner of the headstock and then set the 60 degree points to alignment.

This will give me a more consistent setup....hopefully!

Attachments

Last edited: