Allan,

As a Windows users, you'll have plenty of tools to do what you want. The problem comes if you were a Mac-only user….so no need to worry about it for your needs.

In theory, any application that can print, can access the laser engravers. But I think it would be odd to try, for example, printing from your email app or Microsoft Office.

For AutoCAD, I would suggest trying to print directly to a normal printer…whatever comes out on paper from the view you've printed is what I would expect to see being sent to the engraver. I don't recall though in AutoCAD how to enforce the line widths needed to cause vector or raster operations so you might have to experiment.

I have exported from Inventor to other apps (mostly for use on a ShopBot CNC router). That lets you force a specific view and may be required for setting line widths (if CorelDraw can import what AutoCAD exported).

When moving Inventor pieces over to VCarve (for use with the ShopBot), there's a trick…if you're having problems moving AutoCAD to CorelDraw, ping me and I'll explain how to do it (or Google…but it's tedious to find that way).

I've been told that Illustrator tends to not work quite as well as CorelDraw but haven't bothered trying to prove that since CorelDraw was easier/more convenient for me to use.

While you're learning, you can get by with the much cheaper home license for CorelDraw. It's the full-featured application, but with the licensing restriction to not use it for commercial purposes. Once you're ready to use it for paid work, upgrade to the commercial license. If it doesn't work out and you switch to another app, you're only out the home license cost.

But, lots of sample projects are posted for use with Corel, so using something else may limit your initial options for art to work with…

Yes, if you don't want to cut all the way through, you can indeed just lower the power (or boost the speed). It's not taught that way at the maker space I use but I've done it (figured it out on my own). I call it "vector engraving" and it can speed up certain tasks quite substantially.

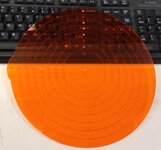

I whipped up a bowl layout gauge a couple years ago…just a bunch of concentric circles with a hole in the center and at specific increments outwards towards the rim (see enclosed photo). Takes a few minutes to draw and if cut from scrap, its materials cost is literally about two bucks (the commercial versions sell for $12-$15).

The first version took about 22 minutes of laser time. The concentric rings were raster-engraved and the text ran at a 45 degree angle from the center.

I tweaked the design to make the concentric rings "hairline" thickness and moved the text so it was horizontal. Ran the raster portion to quickly engrave the text, then the low-power vector portion to make the rings, then boosted the power to cut the tiny holes plus outer rim.

That version takes about 5 minutes total! If I were trying to make some for sale at a craft show, that's a huge difference in my productivity as well as a big reduction in the wear/tear on the laser!

The hi-viz orange turned out to be a poor choice…too dark. There's a florescent yellow that's much lighter…but still has enough color that it doesn't vanish in the clutter on my workbench like the clear version did.

I like the scrap bin at TAP Plastics…easy to get large enough pieces to make jigs, experiment, etc before doing the real thing on higher priced pieces.

Expect to have to experiment a bit on every new project. Print the settings chart and keep it handy…but expect it to be just a starting point. It will tell you what speed/power/frequency combinations to use for raster vs. vector on a variety of materials. But, you'll need to tweak those if your lens is dirty, your laser generator is getting old, your material is slightly different (dark cherry, for example, should laze differently than light cherry).

For bamboo, I find that multiple passes at a lower power produces a more even engraving. Trying to blast it in one pass tends to cause too much variation between light and dark areas (in the bamboo itself) for my tastes.

The laser opens a world of opportunities!! Enjoy!