JD Combs Sr

Member

Just under it.

Purchased one those under-sink water hoses with the stainless steel braid covering to get the covering. Cut one end off of it with a hacksaw then cut about 3" piece off the hose,

worked the braid off of the rubber, tied it with some small wire around a Wall Street II pen tube which I had painted white then cast the whole thing in clear Alumilite. Turned it between centers, applied 4 coats of CA(Alumilite doesn't shine like PR) then polished it with Micro Mesh starting with 2400 then thru 12000.

Assembled it to the rest of the WSII components and wah-lah a stainless steel Wall Street II PENCIL. Didn't have any pens and this 0.5mm pencil had been lying in a drawer for a couple years so I though I would use it.

Some processing comments:

A question, has anyone here on the IAP turned SS braid before. I would like to find out if there is a better way to work with it then the way I had to. I plan on turning the rest of that hose braid into pens. Thought I would try some lightly tinted Alumilite, like say give the SS blue or read tint and see what it looks like.

That stuff is tough. Would never have made it through the process without my carbide tools. It ate my HSS tools alive.

Right off the bat got a big catch with my HSS parting tool trying to take the ends down to the tube ends to square it up. (sometimes I square on/with the lathe rather then a pen mill) Finally got it done with a carbide square scraper. Was holding the casting in my scroll chuck so the catch took a large hunk out of the Alumilite clear down to the braid. Found the piece and super glued it back in place. Very next touch the same piece went flying again. Took a different tack this time. Filled the exposed braid area with thick CA and hit with accelerator. After about three layers of this I had clear acrylic back above the bushing line. Took it a lot easier from then on, no more catches, got the ends squared, went to BTC bushings then turned it as pictured above and the line between the Alumilite and the CA fill is invisible

Right off the bat got a big catch with my HSS parting tool trying to take the ends down to the tube ends to square it up. (sometimes I square on/with the lathe rather then a pen mill) Finally got it done with a carbide square scraper. Was holding the casting in my scroll chuck so the catch took a large hunk out of the Alumilite clear down to the braid. Found the piece and super glued it back in place. Very next touch the same piece went flying again. Took a different tack this time. Filled the exposed braid area with thick CA and hit with accelerator. After about three layers of this I had clear acrylic back above the bushing line. Took it a lot easier from then on, no more catches, got the ends squared, went to BTC bushings then turned it as pictured above and the line between the Alumilite and the CA fill is invisible

.

.

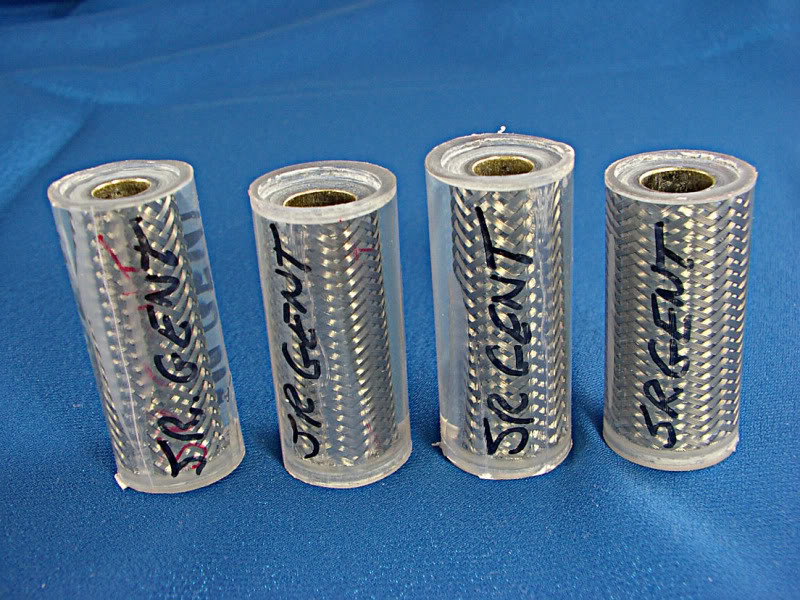

A little closer look.

Thanks for looking and C&C welcomed.

Purchased one those under-sink water hoses with the stainless steel braid covering to get the covering. Cut one end off of it with a hacksaw then cut about 3" piece off the hose,

worked the braid off of the rubber, tied it with some small wire around a Wall Street II pen tube which I had painted white then cast the whole thing in clear Alumilite. Turned it between centers, applied 4 coats of CA(Alumilite doesn't shine like PR) then polished it with Micro Mesh starting with 2400 then thru 12000.

Assembled it to the rest of the WSII components and wah-lah a stainless steel Wall Street II PENCIL. Didn't have any pens and this 0.5mm pencil had been lying in a drawer for a couple years so I though I would use it.

Some processing comments:

A question, has anyone here on the IAP turned SS braid before. I would like to find out if there is a better way to work with it then the way I had to. I plan on turning the rest of that hose braid into pens. Thought I would try some lightly tinted Alumilite, like say give the SS blue or read tint and see what it looks like.

That stuff is tough. Would never have made it through the process without my carbide tools. It ate my HSS tools alive.

A little closer look.

Thanks for looking and C&C welcomed.

Last edited: