PENfinity

Member

I need a segmenting jig made. Is there anyone who makes them?

Looking for something to use with pens?I need a segmenting jig made. Is there anyone who makes them?

Yes! I need a jig that I can use to put & hold segmented pieces together to make a segmented pen blank.Looking for something to use with pens?

A little confused with this statement. As Alan said alot more info is needed to be of help. There are many different styles of segmenting too so each one can be its own challenge and require its own clamping method to go along with own cutting methods. But if you are looking for some standard segmenting with end rings and things like this then I suggest the best jig for clamping is a trusty old piece of angle material. I like to go to home depot and get their aluminum angle. You can get in various sizes and widths. But 1" always works well. Place some wax paper on it and make all the pieces and then clamp against the angle. Here is an example of one that I do.Yes! I need a jig that I can use to put & hold segmented pieces together to make a segmented pen blank.

Thank you for asking... I currently use a WEN bandsaw (but thinking about upgrading to a Laguna). I am interested in cutting any kind of angles and shapes from curved, diagonal, straight, etc. I like your recommendation to contact the maker (which I have done several times with two excellent reknown pen makers, but can't seem to get a response from either of them).You need to supply some information about what segmenting you want to do.

Will you be cutting on a table saw, a band saw, a scroll saw, a mitre saw???

Will you be making straight cuts, angled cuts?

What angles?

You should be able to find good segmenting information in the Library.

A suggestion.... if you see a segmented pen which you admire why not contact the maker and ask them to send you a photograph of the jigs that they used.

I say jigs as you need a fair number of them.

Hope this helps.

Hey thanks for the insight. No I do not have any particular pen blanks in mind. I was just thinking that I could have a jig made to make any kind of segmented pieces I wish...or at least use it as a good starting point to begin with.Do you have a pict of a pen, or link to a pen that you would like to create. There are all kinds of segments and merely saying Angled, straight and curved doesn't help us help you. Most of us do not start machines that make certain kinds of segments and then make a pen because of what our machine makes; Rather, we Start with wanting to make a particular pen with certain design and then make the jig to make the segment. And there are different ways to make certain segments. BUT the design of pen blank that we want - determines or dictates what kind or type of jig to use.

So, if you can, please give us a link or pict of the pen(s) you want to accomplish. We have plenty of accomplished and professional pen turners and pen makers here that can help.

Do you want herringbone, bricks, Celtic knots, stripes and much more, - there are all kinds of segments and different jigs for each type.

There is no "one jig" for all kinds. Each type will usually use different jigs.Hey thanks for the insight. No I do not have any particular pen blanks in mind. I was just thinking that I could have a jig made to make any kind of segmented pieces I wish...or at least use it as a good starting point to begin with.

I understand. I was just saying that's what I had hoped for. Thank you.There is no "one jig" for all kinds. Each type will usually use different jigs.

Wow! Thank u so much!Here is a great place to start to see some of the different styles of segmenting.

https://www.penturners.org/threads/no-comments-just-post-new-segmented-pens-and-likes.111419/

And here is a forum that can help in your quest. Just takes some reading along the way. Have fun.

https://www.penturners.org/forums/segmenting.179/

Okay thank youHere is the order for the proper jig:

1. Figure out which type of pen blank you want to make. Choose that.

2. Make a note of what kind of tools you have. Table saw? Band saw? Byrnes saw? Byrnes or other thickness sander?

THEN:

3. Look/search for making a Jig for XXXX.

Making segments depends upon 1. What type of blank/pen you want to make, 2. the tools you have, then a jig to fit the tools you have.

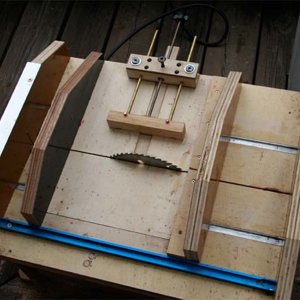

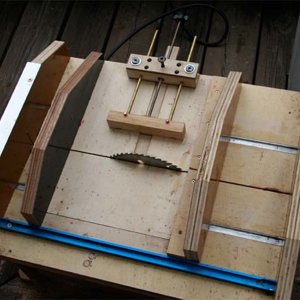

For example, here is a jig I made for different thicknesses of wood segments:

Imported Photo from leehljp

Imported Photo from leehljp. Please edit title and description.www.penturners.org