qquake

Member

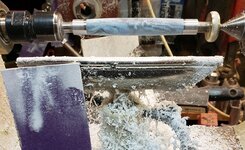

I hate hate HATE turning polyester resin, inlace acrylester, etc. blanks. But every once in a while, I feel the overwhelming urge to punish myself. And I'll admit, this is better than smacking myself in the face with a saucepan. But only just. I tried several different gouges, and three different carbide cutters, including a negative rake. I ended up getting the best results with the flat R2. I've tried the negative rake cutter several times, and it just doesn't blow my skirt up. I don't see what all the hoopla is about.

With the R2 cutter, I've got it mostly smooth. But there's a big chip out that I may have to fill with CA or epoxy. I hope it's worth it.

With the R2 cutter, I've got it mostly smooth. But there's a big chip out that I may have to fill with CA or epoxy. I hope it's worth it.