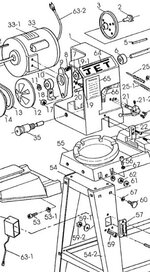

I have a JWL-1236, bought 20+ years ago wheny wife indicated it might be a woodworking activity we could enjoy together. Got it assembled & then she got really sick with our first (of three). ICU-level sick with all three, and then raising them, military moves, family ... Finally started using it a few years ago, mostly pen turning. I've noticed the holes, and turned blanks, don't seem to be quite round. It looks like the headstock is slightly lower than the tailstock, which I don't know how to fix. Doesn't seem to be anywhere I could shim it up.

The tailstock also seems to point off-axis towards the back.

I picked up a double-headed MT2 thing to check alignment, and it's definitely off. The tailstock only accepts a short section before binding

No clue what to do. Any suggestions?

The tailstock also seems to point off-axis towards the back.

I picked up a double-headed MT2 thing to check alignment, and it's definitely off. The tailstock only accepts a short section before binding

No clue what to do. Any suggestions?