bikeshooter

Member

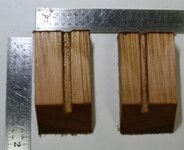

I have almost gotten a bunch of nice spalted oak blanks ready for stabilizing but may have cut them to short. Going to end up at 4 7/8 to 5 inches long. (3/4 square) I'm not a pen maker so I really don't know. Are these to short?

Thanks for your input

Thanks for your input