LL Woodworks

Member

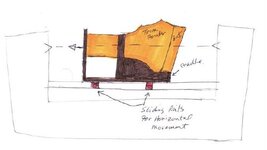

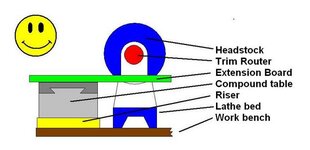

I need to mount a trim router on the bed of my Jet Mini Lathe. My original concept idea was to mount the router in a baltic birch cradle so it is on ceter. The cradle then mounted to a set of rails that will allow horizontal (right to left) movement. Has anyone done this or does anyone has any conceptional design ideas and/or suggestions on how to accomplish this.

To clarify the lathe in the pic is not my Jet Mini and the trim router shown may or may not be the one used. If I can accomplish this with the Ryobi cordless I will - if not I'll buy a corded Porter Cable or DeWalt.

I appreciate any help as I'm not much of a design engineer.

Once again thanks for any ideas and suggestions.

To clarify the lathe in the pic is not my Jet Mini and the trim router shown may or may not be the one used. If I can accomplish this with the Ryobi cordless I will - if not I'll buy a corded Porter Cable or DeWalt.

I appreciate any help as I'm not much of a design engineer.

Once again thanks for any ideas and suggestions.