sbarton22

Member

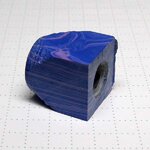

Does anyone have a good method or some kind of live center to put in the tail stock that can give proper support, yet not have a point? Often, I just want something to provide pressure towards the headstock, but I don't want to mar the surface.

I'm sure there are great ideas out there, I haven't been doing this long enough to have a old salty dog trick up my sleeve ready for such an occasion.

I'm sure there are great ideas out there, I haven't been doing this long enough to have a old salty dog trick up my sleeve ready for such an occasion.