X-crAFt custom ink

Member

Hello All,

I hope everyone is having a great day, is healthy, safe and happy.

Just the other week I bought a couple materials from a fellow maker, and I had bought a piece of ebonite.

I have a number of questions about this because I have never seen Ebonite before this point In real life.

As some background about how I turn, I use carbide tools usually NR on the circle cutters.

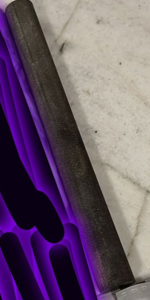

The first thing I am wondering is what type of ebonite I have. I will try to get a picture of it attached below, but I bought what I thought was a black piece of German Ebonite. I have talked to my mentor and he believes it is Japanese. My second question is the rod looks almost brown, dusty and very rough. Will it come out black in the end?

I was also curious about how it turns? what is is most similar to material wise? How does it Drill? How does it sand and polish? What method of sanding would people recommend?

Just overall looking for general advice about the material in general. I am looking for any tips, tricks or advice anyone has.

Open Discussion thread

Have a great rest of your day!

-Alex

Sorry for the Blurred out part of the image. WOrking on some secret projects.

I hope everyone is having a great day, is healthy, safe and happy.

Just the other week I bought a couple materials from a fellow maker, and I had bought a piece of ebonite.

I have a number of questions about this because I have never seen Ebonite before this point In real life.

As some background about how I turn, I use carbide tools usually NR on the circle cutters.

The first thing I am wondering is what type of ebonite I have. I will try to get a picture of it attached below, but I bought what I thought was a black piece of German Ebonite. I have talked to my mentor and he believes it is Japanese. My second question is the rod looks almost brown, dusty and very rough. Will it come out black in the end?

I was also curious about how it turns? what is is most similar to material wise? How does it Drill? How does it sand and polish? What method of sanding would people recommend?

Just overall looking for general advice about the material in general. I am looking for any tips, tricks or advice anyone has.

Open Discussion thread

Have a great rest of your day!

-Alex

Sorry for the Blurred out part of the image. WOrking on some secret projects.