pop1948

Member

Whew!!!!!!

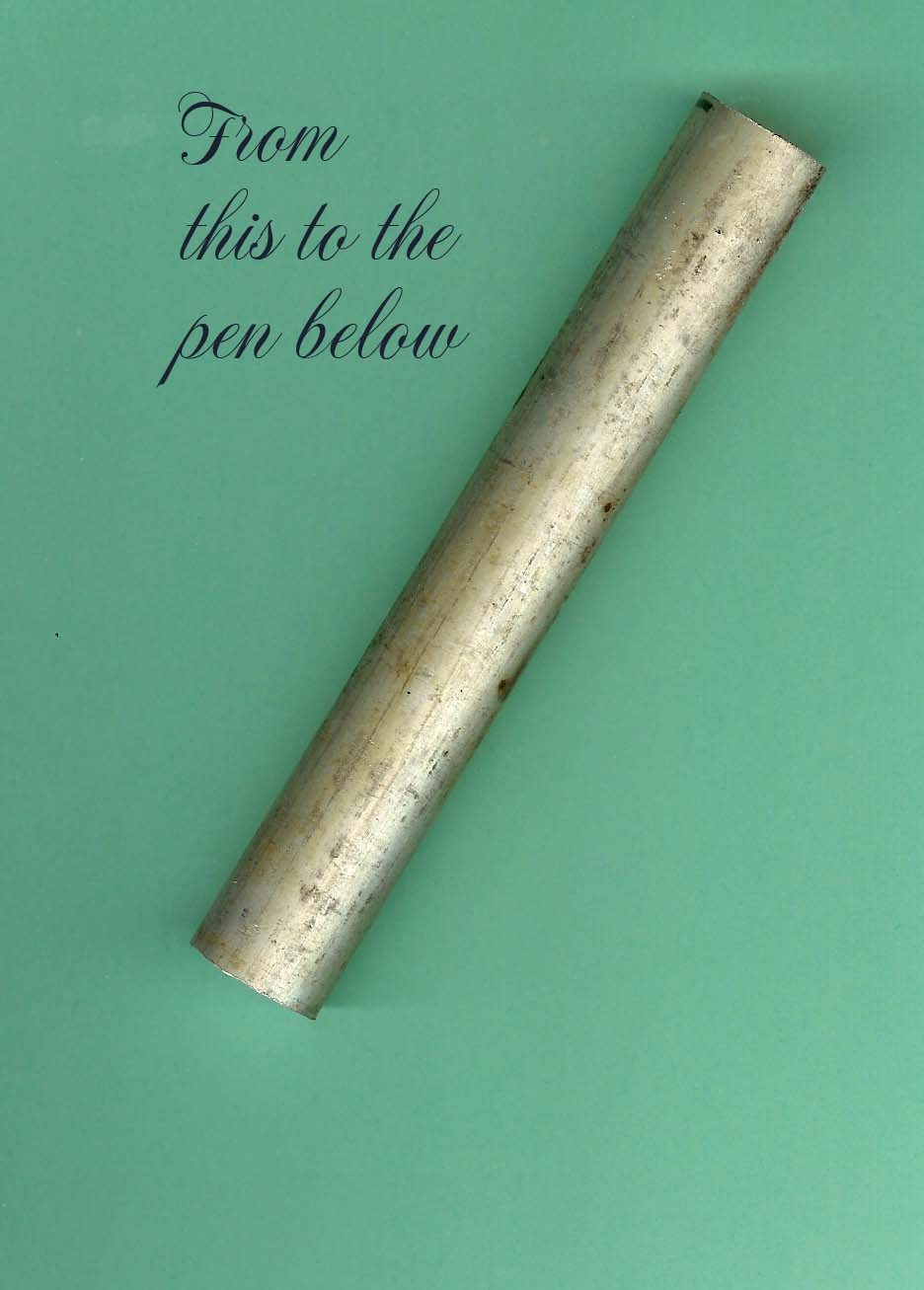

I made a turning tool from HSS key stock steel a small piece about 1/2"X 1/2" it works fair but takes on small bits.So it took me about 3 hrs to turn this pen. I hope to get some cheeper tool from HF to do just these pens, It was a blast and I hope you all like it. PLEASE sent me any help that it might need to make this go faster or easier. Oh yea had a hard time centeritng the round stock. But experience will help. Polished by hand had no buffing wheels, Also thanks to James Mann for the information and insperation

I made a turning tool from HSS key stock steel a small piece about 1/2"X 1/2" it works fair but takes on small bits.So it took me about 3 hrs to turn this pen. I hope to get some cheeper tool from HF to do just these pens, It was a blast and I hope you all like it. PLEASE sent me any help that it might need to make this go faster or easier. Oh yea had a hard time centeritng the round stock. But experience will help. Polished by hand had no buffing wheels, Also thanks to James Mann for the information and insperation