Chasboy1

Member

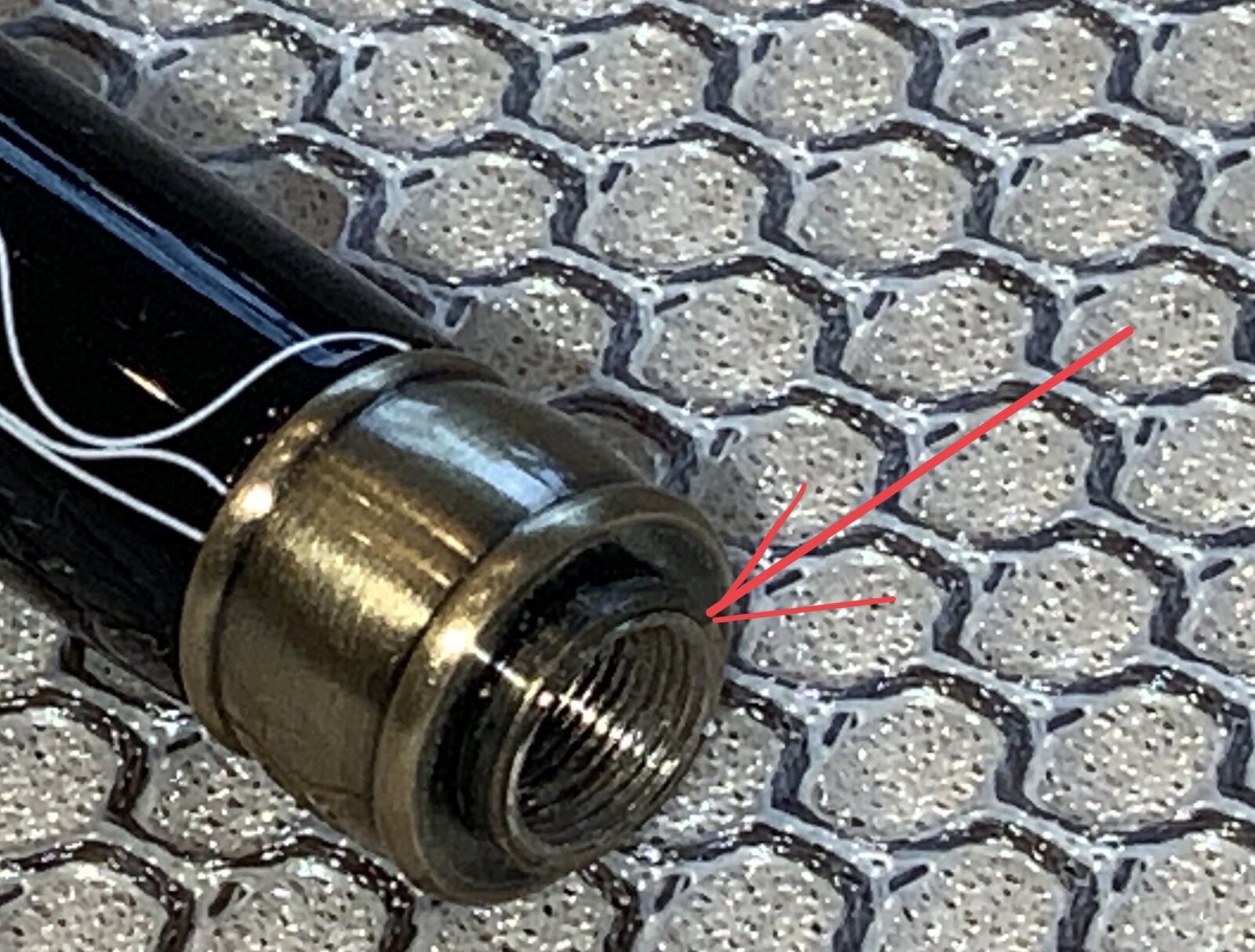

Hi Folks, I guess as you go, mistakes make us smarter. I finished this pen and after assemble realized I should have used a collar to press the center band in. Instead I ended up pushing the threaded section of that part towards the tip of the pen, so when the pen is closed, the refill tip projects just beyond the tip of the pen. This is a gift for a friend and I'd hate to present the pen to him with this as is. Is there a way to disassemble that area of the pen so I can push the threaded section back where it belongs? Thanks