KMCloonan

Member

Like @sorcerertd (Todd), I have been experimenting with Custom Finials (thanks to John Underhill) and custom center bands, as I have been inspired by several that were posted to this forum.

Todd also mentioned it would be nice to see how others make their center bands. I searched the IAP library, and unless I stink at searching, I could not find much info on the topic (there were a couple on custom finials, but not center bands).

I watched a couple you-tube videos on ring making, figuring it could translate to center bands... And landed with the process below, which can use a lot of improvement, but it was a place to start. Any suggestions/Ideas, etc are welcome.

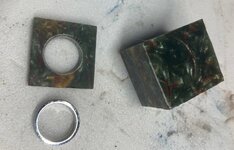

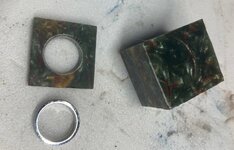

Here is the original Center band from the Diamond Knurl Rollerball:

The ID of the center band is about 0.468", which is basically 15/32. I used a 15/32" drill bit to drill a hole in a scrap of the same blank I used on the pen. The width/Thickness of the center band is about 0.158". I used my bandsaw to cut a 0.160" wafer off of the scrap blank, and I sanded it to the proper thickness.

Then I had to figure out how to turn it. I started with a punch from my punch set as a mandrel, but I could not get a tight fit with the ring blank. I decided to turn my own mandrel out of a spare resin blank to the approximate diameter, with a taper so I can press it on.

I then used some hot glue to hold the ring blank in place (I saw others use tape on the mandrel to make a tight fit - that could also work). I used a live center to support the mandrel, as it was a bit wobbly without that.

I turned the blank down to the final diameter (with a lot of checking with calipers). I then used micromesh to polish it on the mandrel, and then installed it on the pen.

The finial I made was a little thicker than I had planned, but it looks ok, and I did not want to start over.

Todd also mentioned it would be nice to see how others make their center bands. I searched the IAP library, and unless I stink at searching, I could not find much info on the topic (there were a couple on custom finials, but not center bands).

I watched a couple you-tube videos on ring making, figuring it could translate to center bands... And landed with the process below, which can use a lot of improvement, but it was a place to start. Any suggestions/Ideas, etc are welcome.

Here is the original Center band from the Diamond Knurl Rollerball:

The ID of the center band is about 0.468", which is basically 15/32. I used a 15/32" drill bit to drill a hole in a scrap of the same blank I used on the pen. The width/Thickness of the center band is about 0.158". I used my bandsaw to cut a 0.160" wafer off of the scrap blank, and I sanded it to the proper thickness.

Then I had to figure out how to turn it. I started with a punch from my punch set as a mandrel, but I could not get a tight fit with the ring blank. I decided to turn my own mandrel out of a spare resin blank to the approximate diameter, with a taper so I can press it on.

I then used some hot glue to hold the ring blank in place (I saw others use tape on the mandrel to make a tight fit - that could also work). I used a live center to support the mandrel, as it was a bit wobbly without that.

I turned the blank down to the final diameter (with a lot of checking with calipers). I then used micromesh to polish it on the mandrel, and then installed it on the pen.

The finial I made was a little thicker than I had planned, but it looks ok, and I did not want to start over.

Last edited: